In today’s fast-paced industrial environment, material handling has become one of the most critical and demanding tasks across various industries. From manufacturing floors to warehouse operations, the efficient movement of goods directly impacts productivity, safety, and operational costs. Manually handling heavy loads is not only inefficient and labor-intensive but also poses a risk of injury, potentially leading to increased downtime for businesses.

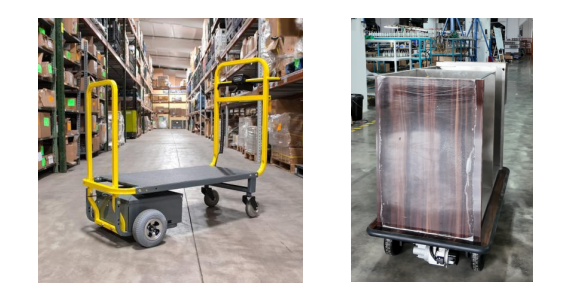

Against this backdrop, an electric trolley power drive kit transforms traditional manual carts into efficient, automated handling tools by integrating advanced motor technology, intelligent control systems, and reliable power sources.

Advantages of the Electric Trolley Power Drive Kit

1. Low Noise

Unlike some traditional mechanical drive systems that generate loud and harsh noises, a modern electric trolley power drive kit is engineered with advanced motor technology and noise reduction designs. This is particularly beneficial for noise-sensitive environments like hospitals, office buildings, and senior living facilities.

2. Improved Efficiency

Manual transportation of heavy loads is limited by the physical capabilities of workers. The drive system enables electric trolleys to move heavy items at a steady and consistent speed, which shortens cycle times, increases throughput, and enables handling larger volumes of work within the same timeframe..

3. Reduced Physical Strain & Injury Risk

Electric trolley power drive kits remove the physical demands of manually moving heavy loads, effectively preventing common occupational injuries like back strain and repetitive stress disorders.

4. High Compatibility

These power assist systems are designed with universal mounting systems that can be easily integrated with various trolley types, platform trucks, and material handling equipment. The modular structure ensures compatibility across different manufacturers and cart specifications.

5. User-Friendly Operation

Most electric trolley power drive kits come with easy-to-use control panels or handles that allow operators to start, stop, accelerate, and decelerate the trolley with minimal effort. The control systems are ergonomic, so that operators can handle the trolley comfortably even during extended periods of use.

6. Energy Efficient & Cost-Effective

A power trolley kit typically utilizes advanced battery technology and motor systems to provide sustained power with minimal energy consumption. Additionally, its durable construction and reliable performance decrease maintenance needs and downtime, resulting in significant long-term cost savings.

Application of the Electric Trolley Power Drive Kit

1. Manufacturing Industry

In manufacturing plants, the movement of raw materials, components, and finished products is a constant and essential activity.

Electric trolleys and platform trucks equipped with power assist systems can be widely deployed to transport these items across production areas, seamlessly moving materials from warehouses to assembly lines. Scissor lift trolleys with integrated drive kits deliver both horizontal transport and vertical positioning, ideal for complex assembly operations and multi-level storage.

2. Logistics & Warehousing

In the logistics and warehousing sector, where goods are continuously received, stored, and shipped, the electric trolley power drive kit plays a pivotal role in transporting heavy pallets, cartons, and containers. It helps accelerate the loading and unloading processes, lowers the time taken to process orders, and enhances inventory management and customer satisfaction.

3. Healthcare & Elderly Care

In hospitals and care facilities, the electric trolley power drive kit can make a significant impact when carrying medical equipment, supplies, and patient care items. Meanwhile, its quiet operation also creates a peaceful and conducive recovery environment for patients

4. Airports & Transport Terminals

From moving luggage from check-in counters to aircraft holds to transporting cargo between different areas of the terminal, the power kit ensures that operations run smoothly, minimizing delays and improving the overall passenger experience.

5. Food Processing & Cold Chain Logistics

In cold storage and food processing environments, power drive kits demonstrate excellent performance in low-temperature conditions, enabling the timely and safe delivery of perishable food items, thus preserving their quality and freshness.

Common Faults of the Electric Trolley Power Drive Kit

1. Device Won’t Start

When the power drive kit fails to power on, first verify the battery’s charge level and ensure all battery terminals are securely connected and free from corrosion. Then, test the power switch to confirm it’s functioning properly and confirm all safety interlocks are engaged and not hindering startup. Lastly, evaluate the control circuit by assessing fuses for continuity and examining wiring for any loose or damaged terminals.

2. Insufficient Driving Force

A depleted battery is often the cause. Another factor could be that the load exceeds the power trolley kit’s rated capacity. Additionally, look for any obstructions or debris caught in the wheels or drive mechanism that could be creating friction and limiting propulsion.

3. Unresponsive or Erratic Control

If the control behaves unpredictably, inspect the control handle or panel for visible damage or loose wiring. Clean the interface thoroughly to eliminate any accumulated dust or contaminants that might interfere with signal transmission.

4. Unusual Noise During Operation

Strange sounds while running may point to issues with the motor, transmission gears, or other moving components. Shut down the system immediately and look over the internal parts for any loosened or broken pieces. Ensure gears are adequately lubricated, as insufficient lubrication can lead to excess friction and noise. If abnormal sounds persist, it could indicate a deeper mechanical fault that warrants professional servicing.

5. Short Battery Life

Begin by confirming that the battery is charging properly. Make sure the charger is operational and the charging duration meets recommended standards. If the battery is significantly aged or degraded, consider replacing it. Also, prolonged usage at high speeds or under heavy loads can accelerate battery depletion, so minimize such demands whenever possible.

Electric Trolley Power Drive Kit from Rotontek

Our newly launched Low noise power trolley kit consists of a handle accelerator, emergency stop switch, electric control box, battery, controller, and brushless motor-driven rear axle, which aims to transform an ordinary manual cart into a high-performance power tool without complex modifications.

With motor power options ranging from 150W to 5000W, the electric trolley power drive kit supports load capacities from 100 kg to 10,000 kg, while speed is continuously adjustable between 1–15 km/h. Operators can effortlessly handle both light and heavy loads, ensuring safe and efficient material transport.

In addition, its energy-saving design sustains power output at minimal consumption, while a modular architecture allows for quick installation. Advanced noise-reduction technology keeps the operation quiet in any environment.

Conclusion

As industries continue to prioritize automation and ergonomic solutions, electric trolley power drive kits will play an increasingly vital role in streamlining logistics, improving workplace safety, and driving operational excellence.

Contact Rotontek today to discover how our electric trolley power drive kits can optimize your workflow, helping you to move toward smarter, faster, and more sustainable material handling.

[…] achieve variable speed functionality in electric drive kits, it’s important to carefully consider both the controller technology and the motor […]

[…] noise generated by a power-assist system can be attributed to three primary […]

[…] their advantages in efficiency, durability, and performance, brushless power assist systems are particularly well-suited for applications that demand reliability, long runtime, and minimal […]