For any supplier, understanding the maintenance profile of your components is critical for customer support and product reliability. The question of whether PMSM motors are easy to maintain directly impacts your operational costs and service planning. This analysis outlines the key maintenance aspects to help you manage your fleet or product line effectively. A clear grasp of these requirements ensures long-term performance and customer satisfaction.

Rotor Magnet Temperature Monitoring

Monitoring the rotor magnet temperature is a fundamental maintenance task for a permanent magnet synchronous motor. The high-strength rare-earth magnets are sensitive to temperature; excessive heat can cause partial or irreversible demagnetization, leading to a permanent loss of torque and efficiency. We recommend using embedded temperature sensors and thermal models to monitor rotor conditions in real-time, especially during high-load or high-speed operations. Preventive maintenance schedules should include verifying the accuracy of these monitoring systems. Ensuring adequate cooling, such as through liquid cooling jackets or forced air, is equally critical to maintain the magnets within their safe operating temperature range, which directly preserves motor performance and longevity.

Stator Winding Insulation Checks

Regular inspection of the stator winding insulation is essential for the operational integrity of any pmsm motor. The insulation system is subjected to significant thermal cycling and electrical stresses from the high-frequency PWM waveforms produced by inverters. Over time, this can lead to insulation degradation, partial discharges, and eventually, short circuits. We advise periodic checks of insulation resistance, typically using a megohmmeter, to detect moisture ingress or contamination. Visual inspections for signs of physical damage, overheating, or carbon tracking are also vital. Keeping the windings clean and dry prevents premature failure, making this a straightforward but non-negotiable part of a predictive maintenance strategy.

Bearing Lubrication Interval Adherence

Adherence to prescribed bearing lubrication intervals is a primary mechanical maintenance requirement. Bearings support the rotor and are subject to continuous mechanical stress. Using the incorrect lubricant type or quantity, or extending service intervals beyond recommendations, can lead to increased friction, overheating, and eventual bearing seizure. We follow manufacturer guidelines for relubrication schedules and lubricant specifications based on operational speed and temperature. For sealed bearings, the focus shifts to monitoring for signs of wear or contamination, as they are typically lubricated for life. Proper lubrication minimizes vibration and noise, directly contributing to the motor’s smooth operation and preventing unplanned downtime.

Conclusion

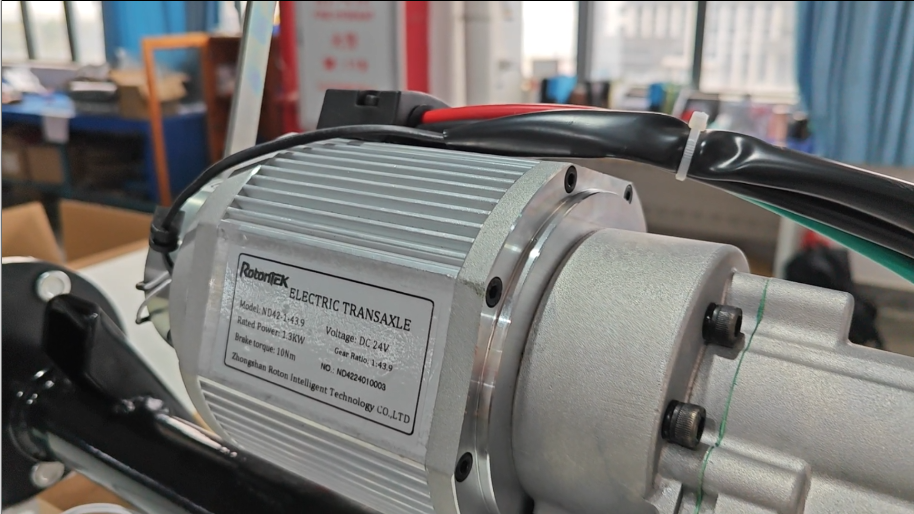

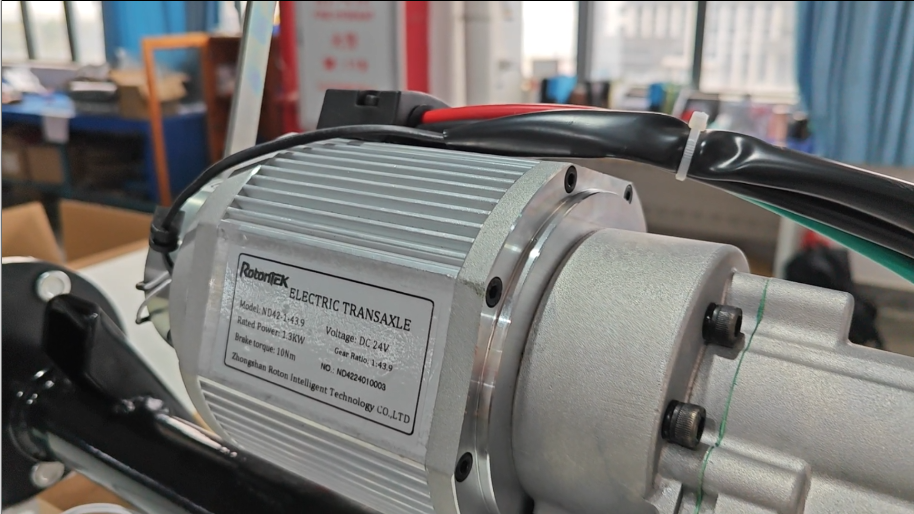

In summary, PMSM motors are indeed easier to maintain compared to many traditional alternatives, thanks to their brushless, durable design. The maintenance regimen focuses on supporting systems rather than the motor’s core magnetic components, offering users predictable performance and reduced servicing costs. For organizations seeking reliable powertrain solutions, this inherent advantage is a significant operational benefit. To explore how these principles are applied in specific products, we invite you to review the technical specifications and support resources available directly from Rotontek.