In the realm of industrial machinery, consistent performance and resilience are paramount. Rotontek addresses these needs through its advanced hydraulic pump and motor pump systems. These products are crafted to withstand rigorous conditions while delivering optimal power and precision. With a focus on innovation and reliability, Rotontek supports a broad spectrum of applications, from heavy industrial tasks to mobile equipment requirements. This article explores the features and advantages of these systems, emphasizing their role in improving operational efficiency.

Innovative Engineering for Superior Performance

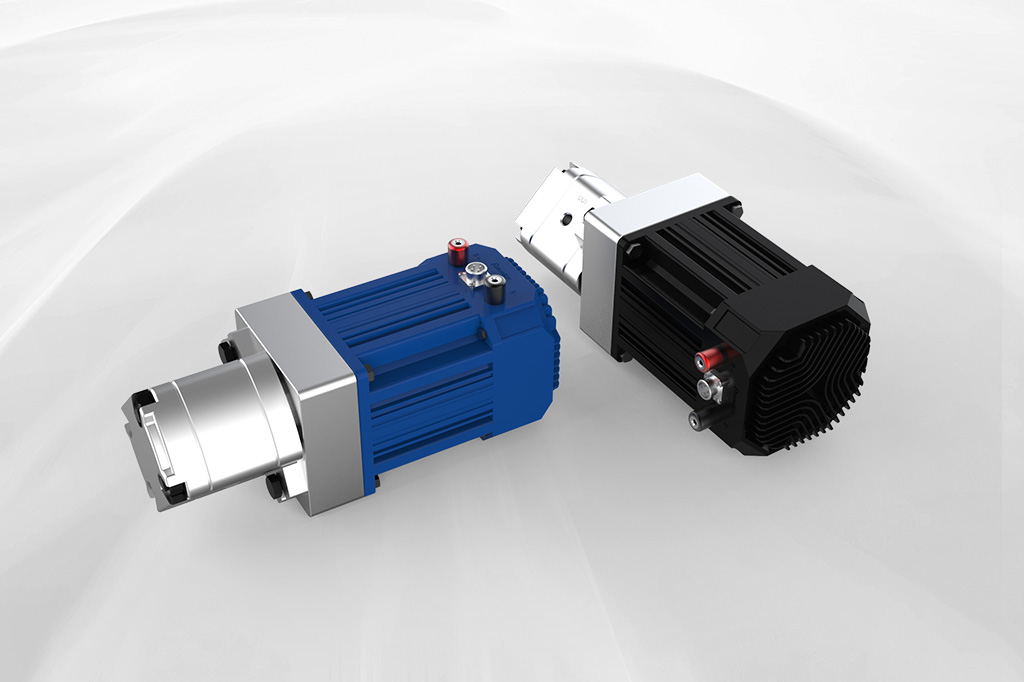

Rotontek hydraulic pump and motor pump units are designed with cutting-edge technology to ensure high efficiency and durability. The integration of brushless motor systems enhances energy utilization and reduces mechanical wear. This approach not only boosts performance but also extends the service life of the equipment. The hydraulic pump components are precision-engineered to maintain steady fluid displacement, critical for applications demanding consistent power output. Similarly, the motor pump designs focus on compactness and adaptability, making them suitable for diverse industrial settings. Rotontek’s commitment to innovation is evident in every hydraulic pump and motor pump unit, providing users with reliable and efficient solutions.

Key Products: 2500W and 800W Integrated Motor Pumps

Rotontek offers two notable products in its motor pump lineup: the 2500W and 800W integrated brushless motor pumps. The 2500W model combines a motor and controller into a single, space-saving unit. This integration streamlines installation processes and reduces associated costs. It operates with low noise and features IP65 protection, making it ideal for demanding environments such as construction and manufacturing. Customization options allow this motor pump to meet specific operational needs. The 800W version, though smaller in power, excels in efficiency and versatility. It is particularly effective in automation systems, medical devices, and smaller machinery where noise and space are constraints. Both units highlight Rotontek’s ability to deliver tailored hydraulic pump and motor pump solutions.

Broad Applications and Operational Benefits

The versatility of Rotontek hydraulic pump and motor pump systems enables their use across multiple industries. In manufacturing, these pumps drive conveyor systems, assembly lines, and robotic arms. The construction sector benefits from their application in heavy machinery like excavators and cranes. Mobile equipment, including agricultural vehicles and utility trucks, also relies on these robust systems. The 2500W motor pump, with its high power output, is suited for material handling and processing tasks. Meanwhile, the 800W model finds its place in precision-dependent applications such as medical technology and laboratory automation. Key advantages include reduced energy consumption, minimal maintenance requirements, and extended operational lifespans. These benefits translate into lower total cost of ownership and enhanced productivity for users.

Conclusion

Rotontek hydraulic pump and motor pump systems represent a fusion of innovation, durability, and practicality. With products like the 2500W and 800W integrated motor pumps, the brand meets the evolving demands of modern industry. These solutions offer reliability and adaptability, supporting a wide range of applications while ensuring efficient performance. Rotontek’s focus on quality and customer-specific engineering reinforces its position as a provider of trusted industrial hydraulic and motor pump technologies.