Extreme cold-chain environments, ranging from -25°C to 4°C with high humidity, pose severe operational hurdles. Traditional manual handling is not only inefficient under such conditions but also exposes workers to significant health and safety risks, including frostbite and slips caused by ice or condensation.

Consequently, the criteria for selecting handling equipment have evolved: it is no longer just about ‘labor-saving’ features. A dedicated power drive kit capable of reliable operation in harsh cold has now become a mission-critical necessity.

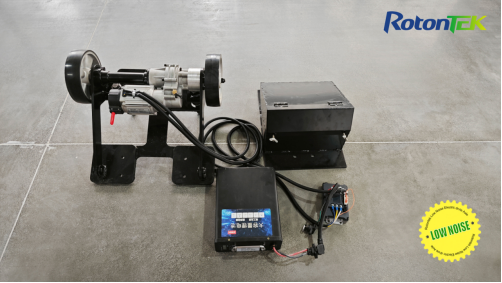

How Rotontek Power Drive Kit Addresses These Challenges

Cold chain operations range from lightweight pharmaceutical picking to heavy-duty industrial pallet movement.

Our electric trolley power drive kit is not merely a standard drive with added insulation; it is a comprehensive technical response to the physics of intense cold and high humidity. With load capacities ranging from 100kg to 10 tons, we ensure that every power-assist system is precisely matched to its specific application.

Challenges of Cold Chain Logistics for Power Drive Kit

1. Thermal Impact

- Battery Performance Degradation: Low temperatures inhibit electrochemical activity, drastically reducing operational runtime and causing voltage instability, which directly undermines equipment reliability.

- Increased Mechanical Resistance:The viscosity of lubricants rises sharply in the cold, forcing motors to overcome significantly higher internal friction during startup. This not only increases energy consumption but also accelerates premature wear of the motor assembly.

- Electronic Component Failure:Standard electronic components, such as capacitors and semiconductors, have limited operational temperature ranges. Prolonged exposure to sub-zero cold can induce parameter drift and lead to outright functional failure, risking a complete system shutdown.

2. Condensation

Moisture in warm air rapidly condenses into water droplets upon contact with cold equipment surfaces. These seemingly tiny droplets can cause serious damage to the drive system.

The risk of short circuits is the most direct threat. Condensed water ingressing into electrical connections or circuit boards can lead to equipment failure or even cause safety incidents.

A consistently humid environment accelerates the oxidation and corrosion of metal components, particularly at contact points between different metals. This corrosion can weaken structural integrity and shorten the lifespan of the power assist systems.

3. Slippage

Cold chain warehouse floors often become exceptionally slippery due to frost or water accumulation during defrosting cycles. Managing heavy loads under these conditions poses a severe challenge to stability control.

Conventional electric trolley power drive kits frequently fail to provide sufficient and controllable traction on such surfaces, which can easily trigger wheel spin, vehicle deviation, or even the overturning of cargo.

4. Noise

Cold chain warehouses are typically enclosed or semi-enclosed spaces, an environmental characteristic that makes noise issues particularly prominent. Prolonged exposure to such an environment exacerbates operator fatigue, diminishes attention and reaction capability, and indirectly heightens accident risks.

In addition, excessive equipment noise may drown out verbal communication and safety warning signals, impairing operational coordination and emergency response efficiency.

How Rotontek Power Drive Kit Addresses These Challenges

Cold chain operations range from lightweight pharmaceutical picking to heavy-duty industrial pallet movement.

Our electric trolley power drive kit is not merely a standard drive with added insulation; it is a comprehensive technical response to the physics of intense cold and high humidity. With load capacities ranging from 100kg to 10 tons, we ensure that every power-assist system is precisely matched to its specific application.

1. Low-Temperature Optimized Brushless Motors

- Specialized Materials & Processes:The motor incorporates low-temperature-resistant permanent magnets and specialized insulation, effectively averting demagnetization and insulation embrittlement under rigorous cold environments.

- Stable Torque Output: Paired with dedicated low-temperature lubricants, our power drive kit overcomes increased internal friction to deliver constant, reliable torque even under heavy-load conditions.

2. Comprehensive Moisture and Corrosion Protection

- Resilient Materials:Critical structural components are treated with industrial-grade anti-corrosion coatings or manufactured from high-grade stainless steel to eliminate rust at the source.

- Hermetic Sealing: All wiring interfaces and electrical connectors utilize high-standard waterproof seals, shielding against moisture ingress (condensation) that often leads to electrical failure.

- Industrial Protection Rating:The entire power drive kit meets IP54 or higher standards, safeguarding internal sensitive circuitry against melting frost or high-humidity environments.

3. Sophisticated Control Algorithms

- Soft-Start Technology:The controller features a “Soft-Start” function that ramps up power output linearly. This mitigates excessive initial torque from overwhelming the grip of the tires, effectively avoiding wheel spin on icy surfaces.

- Anti-Slip Logic: By integrating a proprietary anti-slip algorithm, the system monitors motor feedback in real-time. If traction loss is detected, it instantly adjusts torque output to maintain smooth, safe acceleration and deceleration, preventing cargo from overturning on treacherous floors.

4. Whisper-Quiet Operation

Recognizing the acoustic challenges of enclosed, reflective cold storage spaces, Rotontek has optimized the gear geometry and electromagnetic switching frequencies of the drive system.

By minimizing high-frequency vibrations and mechanical friction, the kit operates at substantially suppressed decibel levels, alleviating operator fatigue and improving overall workplace communication.

Daily Maintenance Points for Cold‑Chain Environments

Proper maintenance is vital to preserve the performance and longevity of your Rotontek power drive kit in harsh cold-chain conditions.

1. De-humidification Procedure

When moving the equipment from a cold warehouse to a warmer area, always place the entire power assist system in a dry, ventilated spot and allow for acclimatization for at least 30 minutes. Assure all surface condensation has evaporated completely before charging or inspection.

2. Key Points for Regular Inspection

Implement a dedicated inspection schedule for the power drive kit, focusing on: tyre wear (to maintain traction), the seal integrity of all cable interfaces (to block moisture), signs of corrosion on structural parts (especially welds and joints), and the lubrication level of moving components.

3. Battery Maintenance Guidelines

Battery care for the power drive kit requires special attention:

- Charging Temperature: Avoid charging in extreme cold. The recommended ambient temperature is 0 °C or higher.

- Charge Cycle:Follow the “shallow charge–shallow discharge” principle, maintaining charge levels between 20% and 80% to optimize battery health.

- Long-Term Storage: If the equipment will be idle, remove the battery and store it separately in a dry, temperature‑controlled environment.

Conclusion

The extreme nature of cold-chain logistics environments places exceptionally rigorous demands on equipment. Our Rotontek electric trolley power drive kit offers a robust answer to the challenges of the freeze. By integrating specialized engineering with intelligent control, it truly achieves reliable, efficient, and safe operation under the most extreme conditions.