Electric drive wheels function by integrating electric motors into the wheels, transforming electrical energy into mechanical motion for direct vehicle propulsion.

Understanding Electric Drive Wheels

Basic Components of Electric Drive Wheels

Electric drive wheels, a critical component in electric vehicles, consist of several key elements. The hub motor, typically rated between 20 to 250 kW, is directly integrated into the wheel and provides propulsion. It eliminates the need for a traditional transmission system, thereby reducing weight and improving efficiency. The power electronics controller, which manages the flow of electrical energy to the motor, is designed to optimize performance and efficiency, often achieving over 90% energy conversion efficiency. These wheels also include sensors for monitoring speed, temperature, and torque, ensuring optimal operation and safety. The battery pack, usually lithium-ion, provides the necessary power, with capacities ranging from 30 kWh to 100 kWh, offering a range of 150 to 300 miles per charge.

Motor Types and Specifications

The electric motors used in these wheels are typically either permanent magnet synchronous motors (PMSM) or induction motors. PMSMs are known for their high power density and efficiency, particularly effective in the range of 85-95%. Induction motors, on the other hand, are praised for their durability and lower cost, though they may be slightly less efficient.

The Role of Electric Motors in Drive Wheels

Electric motors are the heart of electric drive wheels, providing the necessary torque for vehicle propulsion. Their design allows for instant torque delivery, enabling rapid acceleration with speeds varying from 0 to 60 mph in as little as 3 seconds in some models. The motors’ regenerative braking capability converts kinetic energy back into electrical energy, enhancing efficiency and extending driving range. This feature also reduces wear on mechanical brakes, contributing to lower maintenance costs.

Integration with Vehicle Dynamics

Advanced software algorithms control these motors, synchronizing with the vehicle’s overall dynamics. This integration ensures stability, traction control, and a smooth driving experience. The weight distribution in vehicles with electric drive wheels is often more balanced compared to traditional vehicles, leading to improved handling and safety.

Key Advantages

- Increased Efficiency: The direct drive mechanism eliminates energy losses associated with transmissions.

- Reduced Maintenance Needs: Fewer moving parts lead to lower wear and tear.

- Environmentally Friendly: Zero emissions during operation.

Electric drive wheels represent a significant advancement in automotive technology, offering numerous benefits in terms of efficiency, performance, and environmental impact. As technology continues to evolve, these systems are poised to become even more efficient and cost-effective.

Mechanisms of Electric Drive Wheels

How Electric Power Drives the Wheel

Electric drive wheels operate by converting electrical energy into mechanical energy. This process involves several steps:

Direct Power Transfer

Electric motors within the wheel receive power directly from the battery. These motors, typically ranging from 20 kW to 250 kW, convert the electrical energy into rotational force or torque. This direct power transfer allows for immediate response and acceleration, with electric vehicles capable of achieving 0 to 60 mph in just a few seconds.

Efficiency and Energy Use

The efficiency of this process is remarkably high, often exceeding 90%. This efficiency is due to the minimal energy loss in the conversion process. The motors use regenerative braking technology, which recaptures energy during braking, further enhancing efficiency. The average range of electric vehicles using these systems is between 150 to 300 miles per charge, depending on the battery capacity, which can vary from 30 kWh to 100 kWh.

The Transmission System in Electric Drive Wheels

Unlike traditional vehicles, many electric vehicles with drive wheels do not use a conventional transmission system.

Absence of Multi-Speed Gearbox

The single-speed transmission is a common feature in these vehicles. The electric motor’s wide range of operational speeds eliminates the need for multiple gears. This design simplifies the vehicle’s mechanics, reducing weight and maintenance requirements while improving reliability.

Advantages of Simplified Transmission

A major benefit of this simplified transmission is the reduction in manufacturing and maintenance costs. Without complex gear systems, the likelihood of mechanical failures decreases significantly. Additionally, the absence of a gearbox means that electric drive wheels are quieter and smoother in operation.

Key Challenges

- Technology Cost: Despite decreasing prices, the cost of advanced electric drive systems remains high, especially when considering high-performance models.

- Battery Weight and Volume: Large batteries, necessary for longer ranges, can add significant weight to the vehicle, potentially impacting performance and handling.

The mechanisms of electric drive wheels showcase how advancements in electric vehicle technology are revolutionizing the automotive industry. The efficient conversion of electric power to mechanical energy and the simplified transmission systems are pivotal in this transformation.

Control Systems in Electric Drive Wheels

Electronic Control Units (ECUs) and Their Functions

Electronic Control Units (ECUs) are the brains behind the efficient functioning of electric drive wheels.

Core Functions of ECUs

ECUs manage power distribution to the electric motors, ensuring optimal performance under varying driving conditions. They are responsible for processing real-time data from sensors, which monitor aspects like wheel speed, torque demand, and battery status. This data informs the ECU’s decisions on power allocation for maximum efficiency and performance.

Impact on Vehicle Efficiency

ECUs significantly contribute to vehicle efficiency. By precisely controlling motor output, they ensure that the power usage is optimized for the driving conditions, often leading to an overall efficiency rate above 90%. This optimization helps in extending the vehicle’s range and reducing energy consumption.

Integration with Vehicle Dynamics

The integration of electric drive wheels with vehicle dynamics is crucial for performance and safety.

Synchronization with Vehicle Systems

Electric drive wheels are integrated with various vehicle systems such as braking, steering, and suspension. This integration allows for coordinated responses to driver inputs and road conditions, enhancing the overall driving experience.

Enhanced Safety and Performance

Through this integration, vehicles achieve better traction control and stability, especially in adverse weather conditions. The ability to independently control the power to each wheel allows for precise handling, contributing to a safer and more responsive drive.

The control systems in electric drive wheels, especially the ECUs and their integration with vehicle dynamics, play a pivotal role in enhancing the efficiency, safety, and overall performance of electric vehicles.

Electric Drive Wheels vs. Traditional Wheels

Performance Comparison

| Feature | Electric Drive Wheels | Traditional Wheels |

|---|---|---|

| Power and Torque | Instant torque and higher power efficiency. Electric motors can deliver up to 250 kW of power. | Gradual torque build-up, lower power efficiency. Standard combustion engines average around 100 kW. |

| Acceleration | Rapid acceleration. 0 to 60 mph in as little as 3 seconds. | Slower acceleration due to mechanical delays in power transmission. |

| Noise and Vibration | Minimal noise and vibration due to fewer moving parts and smoother operation. | Higher noise and vibration levels due to engine and transmission mechanics. |

| Maintenance Requirements | Lower maintenance needs due to fewer mechanical components. | Requires more frequent maintenance due to complex engine and transmission systems. |

Energy Efficiency and Environmental Impact

| Feature | Electric Drive Wheels | Traditional Wheels |

|---|---|---|

| Fuel Efficiency | Highly efficient, with over 90% energy conversion efficiency. | Lower efficiency, with average internal combustion engines at about 25-30% efficiency. |

| Emissions | Zero emissions during operation, contributing to reduced air pollution. | Produces CO2 and other greenhouse gases, contributing to air pollution and climate change. |

| Energy Source | Powered by electricity, which can be sourced from renewable energy. | Dependent on fossil fuels like gasoline or diesel. |

| Lifecycle Impact | Better long-term environmental impact, though battery production and disposal pose challenges. | Significant environmental impact due to emissions and reliance on non-renewable resources. |

Key Takeaways

- Electric drive wheels offer superior performance, efficiency, and environmental benefits compared to traditional wheels.

- The shift towards electric mobility is crucial for reducing transportation-related emissions and combating climate change.

Maintenance and Troubleshooting

Common Maintenance Practices for Electric Drive Wheels

Maintaining electric drive wheels is crucial for ensuring longevity and optimal performance. Here are key practices:

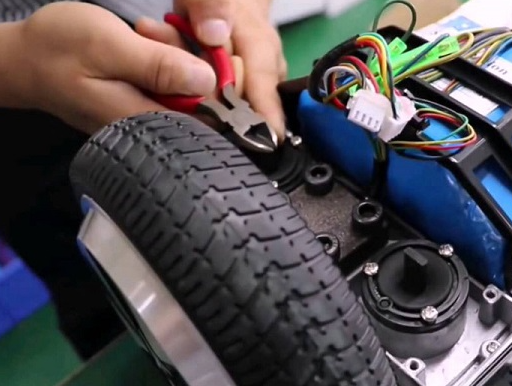

- Regular Inspection of the Motor and Components: It’s important to check for any signs of wear or damage, particularly in the motor’s bearings and electrical connections.

- Battery Care and Management: Regularly monitor the battery’s health, including charge levels and temperature. Lithium-ion batteries, commonly used in these systems, have a lifespan of about 8-10 years.

- Software Updates: Keep the vehicle’s software up-to-date to ensure optimal performance and efficiency. Manufacturers often release updates that can improve the system’s functionality.

- Tire Maintenance: Since electric vehicles can be heavier due to the battery, tire wear should be monitored closely. Rotate tires regularly to ensure even wear.

Diagnosing and Troubleshooting Common Issues

Identifying and resolving issues in electric drive wheels can prevent more significant problems down the line.

- Reduced Range or Efficiency: If the vehicle’s range decreases noticeably, it could indicate battery health issues or problems with the motor’s efficiency.

- Unusual Noises or Vibrations: These can be signs of mechanical issues in the motor or wheel assembly. Prompt inspection is advised.

- Warning Lights or Error Messages: Pay attention to any dashboard warnings. Use a diagnostic tool or visit a professional for a detailed check-up.

- Braking Irregularities: If regenerative braking seems less effective, it could be a sign of issues with the motor or control systems.

Key Points to Remember

- While electric drive wheels require less maintenance than traditional systems, regular check-ups are vital.

- Early detection and resolution of issues can prevent costly repairs and extend the lifespan of the vehicle.

Technological Innovations in Electric Drive Wheels

Recent Advances in Technology

The field of electric drive wheels has seen significant technological advances, enhancing performance and efficiency.

- Improved Motor Efficiency: Modern electric motors now boast efficiencies of over 90%. Advances in motor design and materials have led to more power output with less energy consumption.

- Battery Technology: The development of higher-density lithium-ion batteries has extended vehicle ranges, with some models now offering over 300 miles on a single charge.

- Regenerative Braking Enhancements: Recent improvements in regenerative braking technology have made this system more efficient, contributing to energy recovery and extended battery life.

- Smart Control Systems: Enhanced ECUs and software algorithms allow for more precise control over motor output, improving vehicle handling and safety.

Future Trends in Electric Wheel Drive Technology

The future of electric drive wheels is promising, with several trends shaping its development.

- Integration of AI and Machine Learning: The use of AI will enable more adaptive control systems, optimizing performance based on real-time driving conditions.

- Autonomous Vehicle Compatibility: Electric drive wheels are being developed to be fully compatible with autonomous vehicle technology, allowing for smoother and more efficient operations.

- Sustainable Materials: Research is focusing on using more sustainable and less environmentally damaging materials in motor and battery production.

- Rotontek Innovations: Companies like Rotontek are at the forefront of these innovations. They deliver mobile drivetrain and motion solutions for various industries, with their wheeldrives designed as a monoblock, integrating motor, reducer, and wheels into an all-in-one solution. This design simplifies vehicle installation and enhances overall performance.