For electric dolly, when choosing the right drive axle, controller and throttle, it is recommended to consider based on the particular needs. You should firstly learn about the market dynamics of electric dolly, and then further understand these three core components regarding their values and personalized combination. It is advised to consult well-known brands to get the one-stop solution which helps to ensure the compatibility and performance of them.

Market Comparison Study

When selecting the core components of electric dollies, it is necessary to understand the current market situation and product trends. The world electric dolly market has shown a steady rise which has achieved $5 billion in 2023, and this number is expected to rise to $7.5 billion by 2028, with an eight year compound annual growth rate over that time period equaling 8.4%. While the Chinese demand for electric dollies is large and growing, as the $2.2 billion that the market was valued at in 2023 is a number that is expected to grow by 10% over the next five years.

Rotontek, as today’s industry-leading company, has applied advanced technology to product technology, improving the product performance of electric dollies and launching efficient and durable electric dolly solution with 15 % more energy efficiency, which has been widely used in China among various industries. The price of electric dollies varies from $500 to $3000. The price of Rotontek’s electric dollies starts from $800 and can be customized to meet the needs of small-scale to large-scale enterprises. In Rotontek’s solution, you can choose the core components of the product in addition to price, and further consider factors such as performance, life, and after-sales service, which is more cost-effective than buying ready-made electric dollies.

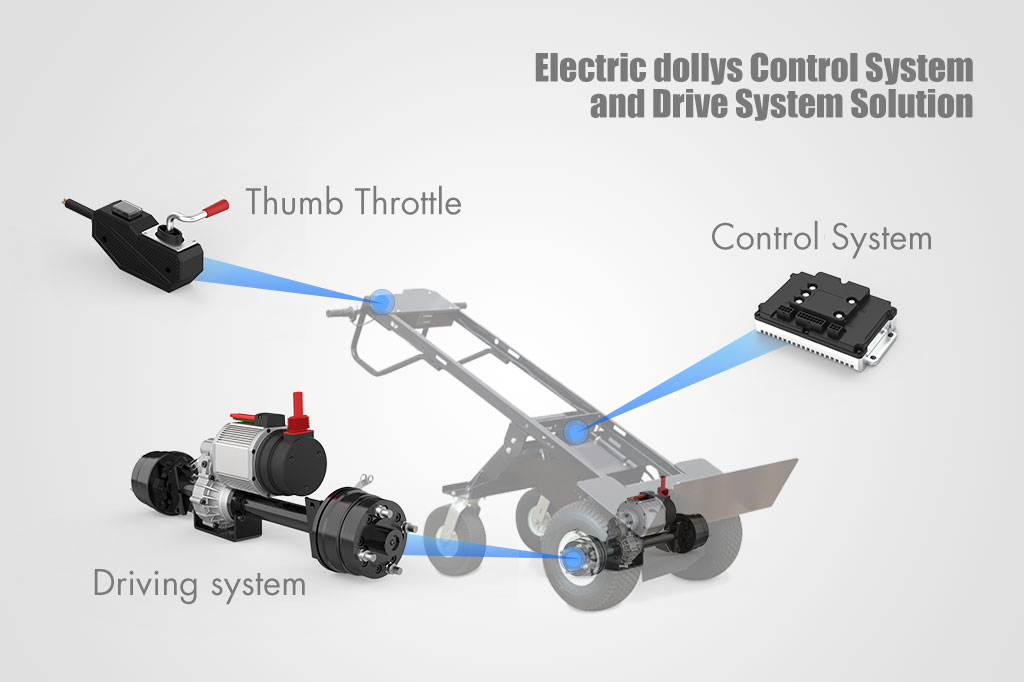

Three Core Components of Electric Dolly

The three core components of an electric dolly are the drive axle, controller, and throttle. Choosing the right three components to some extent is the same as finding the right business strategy for a company, which largely improves the efficiency and performance of the electric dolly. The following is an elaborate introduction to the three components and their core values:

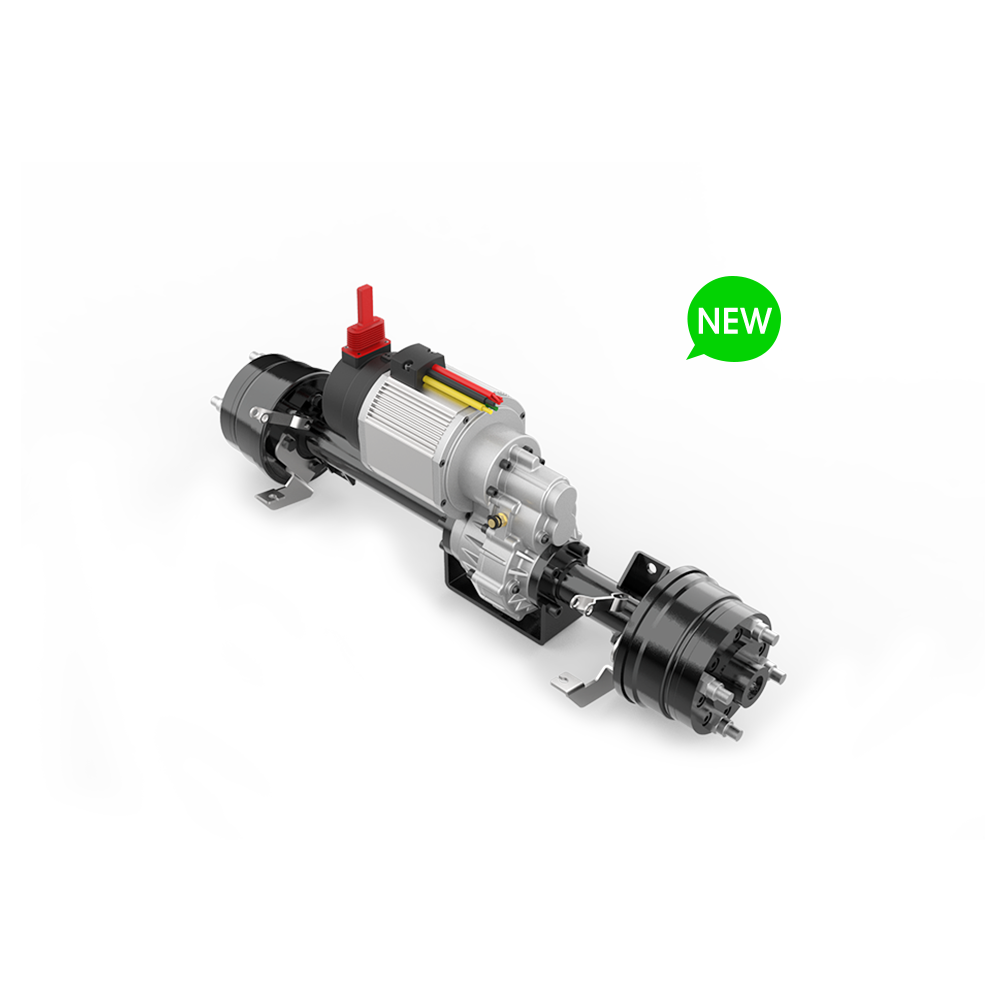

Drive Axle

The drive axle is the power transmission device of electric dolly. It transmits the power of electric dolly motor to the wheel and provides the necessary traction and stability for electric dolly. Over 80% of electric dolly failures are directly related to the drive axle according to the market research, which shows how important the correct choice of the drive axle is.

A drive axle with a differential lock function can increase traction on rough roads by 30% and improve operational stability.A high-torque drive axle can remain stable on a 15 degrees slope but slip on a 10-degree slope in regular drive axle.

Controller

The controller serves as the “brain” of an electric dolly, adjusting current and speed to ensure the efficient and stable running of the motor. According to market data, the power consumption of a low-quality controller is 15% higher than that of a high-quality controller. A high-quality controller can reduce battery consumption and is highly marketable.

Over 300 logistics companies have had their operation efficiency increased by 25% and failure rates reduced by 18% since their electric dollies were equipped with smart controllers. The choice of a controller also affects the safety performance, and some high-end controllers are equipped with anti-lock and automatic breaking systems in the event of an emergency, providing a 50% improvement in safety performance.

Throttle

The throttle is a very crucial device in operating the electric dolly, directly affecting the ease of operation. There are mainly two types in the market: thumb throttles and trigger throttles.

Thumb throttles have the advantage of being precise and sensitive to the change in speed and reduce the hand ache rate by 40% after continuous 8-hour operation. A survey of some logistics companies shows that the reaction time of a thumb throttle is 0.1 sec, while the reaction time of a trigger throttle is 0.2 sec, meaning that a thumb throttle can significantly reduce the operation time and power consumption.

Trigger throttles are very durable and operation-stable, suitable for operation for a long time in harsh environments, but thumb throttles provide a better choice for most companies, since regular enterprises have relatively stable operating environments.

How to Choose Reliable Solution Provider

IDC data shows that more than 70% of companies choose suppliers based on the technical support capabilities and product quality they have. A reliable supplier can provide you with the same stable and efficient products. Rotontek products are of high quality, with a 96% satisfaction rate for company customers, presenting the products, as well as full technical support after the sale, so that customers will not have any worries during use.

Actually, in Rotontek’s customer case studies, customers who use their solutions tend to have fewer equipment failures than industry averages, with failure rates down 15% and operational efficiency up 10%, allowing the features of a quality supplier to truly present itself in a tangible way.

According to market research, suppliers who have a complete after-sales service offering can increase their customers’ retention rates by an average of 18%. Rotontek’s after-sales service team also performs well in this regard. The team can provide customers with rapid response service and professional solution support as soon as customers have problems with the equipment for timely handling.That’s why as long as you choose Rotontek, many of the companies using Rotontek solutions have equipment failure rates, with 20%, significantly improving production efficiency compared to other manufacturers, demonstrating Rotontek’s strength.

Personalized Component Customization

In terms of customization services, Rotontek is the leader in the industry. Similar to recommendations based on client preferences seen on e-commerce platforms, Rotontek offers various customized options for the components, and they can always identify the solution that suits the customers best. According to Gartner’s research, customized products have accounted for more than 35% in the global electric dolly market. Furthermore, custom services by Rotontek received the high score of 95% in customer satisfaction surveys.

1500W brushless DC drum brake full floating axle

Rotontek’s 1500W brushless DC full-floating axle was chosen, which provides a load of up to 600 kilograms, stabilizing in a heavy logistics transport task. Its product test proves that the noise is less than 50db, which serves as 15db lower than its equivalent market product, providing the ultimate comfort. The component uses forged alloy steel gears to have a fine grinding, which ensures the average lifespan that excels 10,000 hours or 40% more durable than traditional gears.

The 2KW Brushless Controller

As for the controller, the Rotontek’s 2kW brushless controller was used. It is capable of an accurate output, reaching a higher degree of intelligence. The controller’s efficiency reaches up to 90% to save the use of energy, and it has five-speed modes to cater to different tractions. The controller’s energy consumption is lower than ever at a weight of a few light-loads. The laboratory data show it is 18% lower. And the controller’s performance stability has been enhanced by 22% from that of the heavy loads.

Thumb Throttle

The throttle of the Rotontek is a more intelligent thumb type that has been gaining the favorites and popularity of the market among other similar products. The throttle’s sensibility boasts a 0.1-second response, which serves as 50% faster than the traditional products. It is serving as 75% of the warehouse industries according to the market research, activities which demand accurate control. And the ergonomic design of the controller decreases the use of it by 40% fatigue, increasing the comfortability and efficiency by an enormous degree while working for long periods.

Both Amazon and Walmart, multinational giant companies, prefer customized solutions of logistics offered by Rotonek in response to specific requirements for their businesses. According to the market analysis, the operational service efficiency in corporations which use customized solutions by Rotontek has increased by 25%, while operational cost decreased by 20%. These customized options enhance market competitiveness of companies by 30% and optimize operational workflow at a corporate level by reducing the level of replication and increasing the level of automation.