In the selection of a BLDC motor suitable for a project, the focus should be on power matching, torque output, and protocol compatibility. For example, in transporting 500 kg of cargo, an AGV should be equipped with a motor with 50Nm peak torque, 800W power, and support the CAN-BUS protocol. This will improve automation accuracy by 35% and increase operating endurance by 6 hours.

Electric Cleaning Car

When choosing a motor, actual needs shall be considered. To an electric cleaning car that requires continuous operation, rated power and continuous working time will be the most important parameters. For example, if a standard cleaning car needs to work for 8 hours a day, then a BLDC motor with continuous power of 1000W and a speed of 3000 RPM can meet the demand. If it is to handle slopes or high-resistance surfaces, the peak torque has to be over 60Nm. Assuming the fully loaded cleaning car weighs 200 kg, the starting torque of the BLDC motor has to at least exceed the calculated load requirement.

Is higher motor power always better? That’s a myth. Higher power means more current consumption. A regular 48V 20Ah battery, working with an 800W motor, would run for about 3 hours. When changing to a 1200W motor, it runs for 2 hours. Although power consumption is proportional to power, runtime becomes a key variable in your budget.

Some BLDC motors are designed with sophisticated torque control capabilities to precisely control speed and save energy. For instance, in a factory cleaning project, the application of intelligent speed-regulating BLDC motors increased comprehensive efficiency by 15% and reduced the rate of equipment failure by 30%. Some such motors are fitted with heat sinks and large casings, which can be as big as over 200mm in length. Compact electric cleaning cars would require advance measurement of space in the motor compartment.

Unmanned Patrol Vehicles

A patrol vehicle must run for over 8 hours a day in a large park, so motor performance is critical. Insufficient power leads to breakdowns, and inadequate endurance results in mission interruptions!

If there is an operating speed range of 10-15 km/h for a patrol vehicle and with a weight totaling 120 kg, the BLDC 500W will be sufficient for flat roads. Taking into account outdoor slopes and sudden accelerations and braking responses, the consideration should at least be 1.5 times that in terms of power margin.

Unmanned patrol vehicles often work in complex environments: rain, dust, and extreme temperatures. Choosing a BLDC motor with an IP55 or higher protection rating is very important. In one security project, a batch of patrol vehicles equipped with IP44 motors experienced water ingress and short circuits after two consecutive days of heavy rain, which caused a 5-day delay for the project and resulted in a loss of $10,000.

Smart control is the trend. Today, most high-end BLDC motors are equipped with Hall sensors and adaptive torque adjustment. “Unmanned patrol vehicles need more than speed; they need stability and flexibility during mission execution,” said a CTO of a technology company at a security exhibition. While patrol vehicles make a turn or change their direction, adaptive torque adjustment avoids loss of control and enhances dynamic response. The response time with this technology is more than 20% less compared to traditional motors, which is ideal for unmanned tasks.

Before choosing a motor, measure the installation space of the vehicle and then choose compact but highly efficient cooling models. Some compact BLDC motors use an aluminum alloy structure and high-efficiency heat sink to keep output stable even at 70°C.

Programmability

In the selection of a BLDC motor for an electric amusement vehicle, attention needs to be paid to power matching and load capacity. Generally, electric amusement vehicles transport 6 to 12 passengers, with the fully loaded weight reaching about 600-800 kg. If the power of the motor is only 500W, it will not be able to handle even flat road operation, and with slopes over 2 degrees, it will experience speed drops and over-temperature conditions. These require motors upwards of 1kW and more, which will be able to provide very high peak torque-for example, more than 60Nm.

Low noise is valued highly in control in amusement equipment. A number of low-end motors make a noise of more than 65 dB when running at high speed, equal to an idle car. High-quality BLDC motors feature brushless design and vector control technology that keeps the noise level below 40 dB and are almost silent even near the vehicle body. Some of the older models of BLDC motors, while powerful, have abrupt starts and acceleration, causing noticeable jolts for passengers. Good motors use vector algorithms to optimize their startup process, dividing torque output into multiple “segments” for smooth transitions up to 2000 RPM for enhanced ride comfort.

Some new BLDC motors are fitted with overload protection and temperature monitoring modules. If there is a high load or high temperature, the system will automatically adjust the output power to prevent burning of the motor. “Intelligent systems can improve operational efficiency by 20% and reduce accident rates,” said an industry expert.

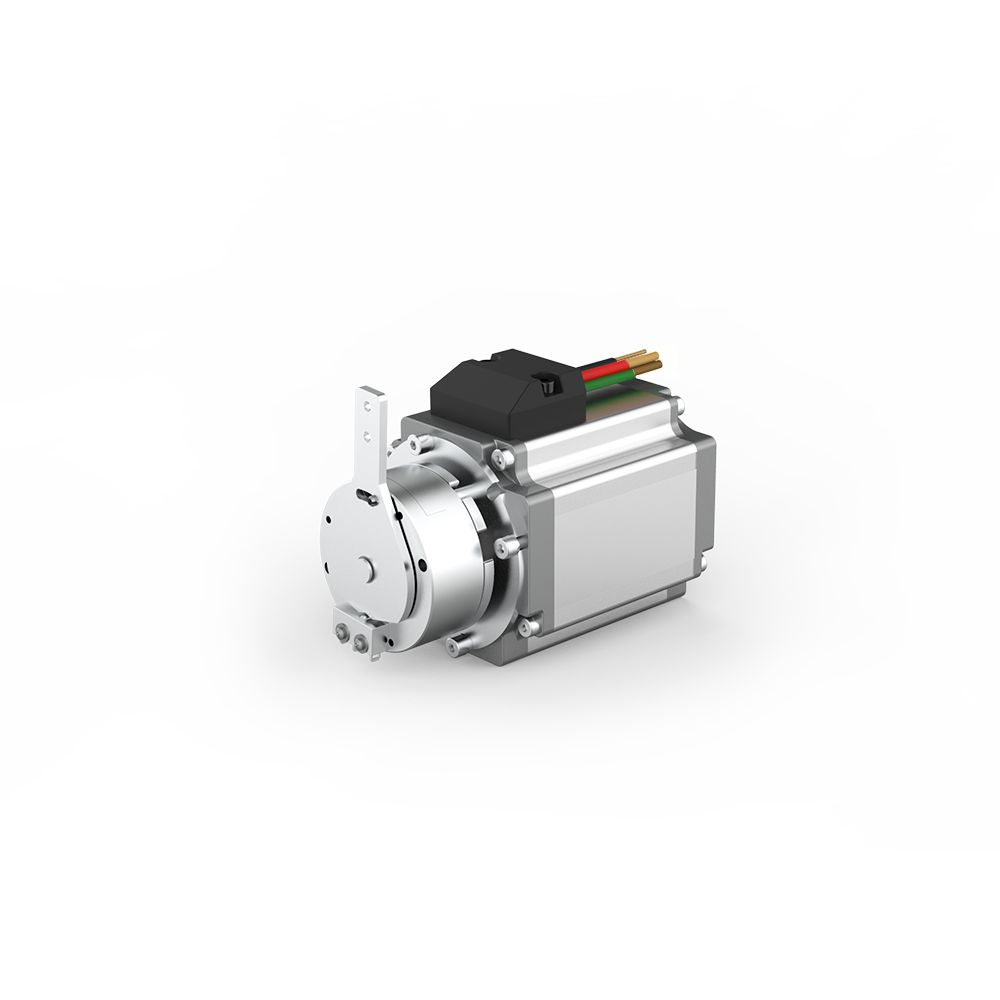

Automated Guided Vehicle

AGVs have to make their way through narrow warehouse aisles and handle heavy load transportation, which involves complex parameters like power, torque, endurance, and precision.

For instance, the transportation of 500 kg at a speed of 1 m/s requires that, in such cases, a peak torque of less than 50Nm can hardly start an acceleration; this can highly affect delivery efficiency and delay logistics for the whole production line by 10% to 20%.

Higher power means higher energy consumption and more heat generated. A 48V 40Ah battery, when combined with a too powerful motor, can have its endurance reduced from 6 hours down to 3 hours. An appropriate rated power to maximum output ratio needs to be chosen in order to balance performance and endurance. AGVs require high precision during navigation. In positioning at the millimeter level, for example, the Hall sensor accuracy of BLDC motors needs to achieve a high standard.

During long operation, the internal temperature of the motor can be higher than 80°C. If the cooling performance is poor, the service life of the motor will be greatly reduced. Compact and high-load AGVs often have little room for large cooling systems. Choose a motor with an aluminum alloy shell and a well-designed heat sink to maintain operating temperatures below 65°C for better durability and system stability.