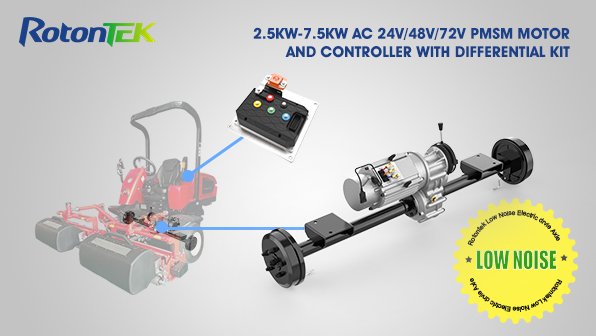

At Rotontek, we aim to delivering quiet, reliable drive solutions that elevate the performance of commercial and consumer mowing e quipment. The Low-Noise Electric drive Axle is engineered specifically to meet the demands of engineers, wholesalers, manufacturers, and procurement specialists seeking durable, low-vibration components for lawn mower transaxle applications.

Precision Materials and Forged Alloy Steel Gearing

We manufacture every gear in the Low-Noise Electric drive Axle from forged alloy steel to ensure maximum strength and longevity. Using forged alloy steel reduces the risk of fatigue and failure under heavy, continuous loads typical in lawn mower transaxle systems. In addition, fine tooth grinding is applied to all gear profiles to achieve exceptional surface finish and tooth accuracy. This precision process minimizes meshing noise and wear, which directly contributes to longer service intervals for lawn mower transaxle assemblies used in material handling, agricultural machinery, and cleaning vehicles.

Advanced Processing for Low Noise and Comfort

Our Low-Noise Electric drive Axle achieves quietness not by chance but by design. Fine tooth grinding combined with stringent gear tolerances reduces transmission vibration and the discrete noise that can arise from imperfect gear contact. Making your driving quieter and more comfortable is a core outcome: quieter operation is particularly valuable for urban low-speed electric vehicles, unmanned vehicle drive systems, and golf equipment where operator comfort and low acoustic signature matter. Quiet operation is achieved through high-quality materials and precision processes — and our quality control verifies that each lawn mower transaxle component meets noise and performance targets before shipment.

Durability and Application Versatility

We understand procurement specialists and OEMs require components that perform across diverse operating environments. The forged alloy steel gears in the Low-Noise Electric drive Axle provide the mechanical resilience needed in electric drive systems for tricycles and quadricycles as well as in heavy-duty lawn mower transaxle applications. Fine tooth grinding not only reduces noise but also improves load distribution across gear teeth, enhancing fatigue life—critical for corporate bulk-order clients and manufacturers producing fleets of cleaning vehicles or agricultural machinery.

Why Choose Rotontek for Your lawn mower transaxle Needs

We combine material science, manufacturing precision, and rigorous testing to deliver a Low-Noise Electric drive Axle that reduces acoustic footprint while improving reliability. For engineers, the benefits include repeatable gear geometry and consistent backlash control; for wholesalers and brand companies, the advantages are lower warranty claims and higher end-customer satisfaction. Our commitment to quality means every lawn mower transaxle leaving our facility reflects the benefit of forged alloy steel construction and the finishing accuracy of fine tooth grinding.

Conclusion

We at Rotontek design the Low-Noise Electric drive Axle to be a high-performance, quiet, and durable choice for lawn mower transaxle and related electric drive applications. Quietness is a result, due to quality material, precision process — and we stand behind the performance of our components for material handling, golf equipment, agricultural machinery, cleaning vehicles, unmanned vehicle drive systems, and urban low-speed electric vehicles. Choose Rotontek when quiet, long-lasting drive solutions are required.