The rapid global shift toward electrification is not just a trend; it’s a fundamental change in how the world moves. At the heart of every Electric Vehicle (EV)—from the smallest mobility scooter to the heaviest industrial transport—lies the motor control system. It is the critical technology that translates the driver’s intent into precise, efficient motion. Without a sophisticated control system, the potential of the electric motor remains untapped.

At Rotontek, we specialize in the complete electric drivetrain solution, recognizing that the efficiency and performance of an EV are determined by the synergy between the motor, the gearbox, and, most importantly, the controller. Our focus is on providing robust, high-precision components for OEMs, manufacturers of low-speed electric vehicles, material handling equipment, and specialized industrial automation applications. This article provides a deep dive into the function, components, and significance of this crucial EV technology, highlighting how our integrated systems drive better performance.

The Brain of the Drivetrain: What is Motor Control in EV?

The EV motor control unit (MCU), often simply called the motor controller, is the electronic brain that manages the flow of electrical energy between the high-voltage battery pack and the electric motor. Its core function is to regulate the speed, torque, and direction of the motor based on inputs from the vehicle’s accelerator, brake pedal, and other sensors.

In simple terms, an EV motor is typically an AC motor, such as a Permanent Magnet Synchronous Motor (PMSM) or an Induction Motor, or a BLDC motor (Brushless DC). However, the vehicle’s battery stores power as Direct Current (DC). The motor controller’s primary task is to act as an inverter, converting the battery’s DC power into the variable frequency, variable voltage Alternating Current (AC) required to spin the motor. This real-time, high-speed conversion is what allows for smooth acceleration, deceleration, and energy management.

The Essential Functions of an EV Motor Controller

A modern motor control unit does far more than just turn the motor on and off. It performs several critical functions vital to an EV’s operation and overall efficiency:

Power Conversion and Control: It uses power electronic components, like MOSFETs or IGBTs, to rapidly switch the DC current, creating the necessary AC waveforms for the motor. Advanced control algorithms, such as Field-Oriented Control (FOC), enable separate and precise regulation of the motor’s torque and flux, maximizing efficiency across all operating speeds.

Torque and Speed Regulation: The controller continuously monitors motor and vehicle parameters, adjusting the current to meet the driver’s command. Whether the vehicle is starting up, climbing a hill, or maintaining a steady cruise, the controller ensures a smooth and immediate response.

Regenerative Braking: This is a key feature of electric mobility. When the driver slows down, the controller reverses the process. It allows the motor to act as a generator, converting the vehicle’s kinetic energy—which would otherwise be wasted as heat in friction brakes—back into electrical energy and sending it to recharge the battery. This feature significantly enhances a vehicle’s range and longevity.

Protection and Diagnostics: The MCU constantly monitors temperature, current draw, and voltage to protect the expensive motor and battery components from overload, short circuits, and overheating, ensuring the system’s longevity and safety.

Enhancing Performance with Rotontek’s Integrated Solutions

Achieving optimal EV performance is not about buying separate, standalone components—it’s about seamless integration. Our philosophy at Rotontek is to deliver complete, optimized systems. Our expertise goes beyond the motor itself, focusing on the sophisticated integration that defines a truly efficient vehicle.

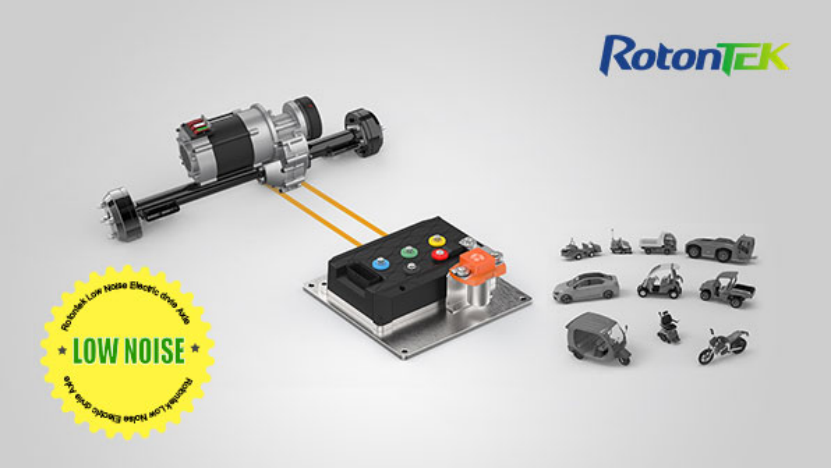

We offer a range of comprehensive drive systems, including our high-performance transaxles and integrated drive axles, which bundle the motor, gearbox, and often the controller, into a single, compact unit. This integrated design is essential for manufacturers of vehicles where space and weight are critical constraints.

Take, for example, our permanent magnet brushless transaxle series, which are designed to support a wide range of low-speed electric mobility applications, from small electric tugs to golf carts. The 800W Permanent Magnet BLDC Transaxle ND42 800 is a prime example of our commitment to integrated quality. This specific transaxle is a single, robust unit, combining a high-efficiency brushless DC motor and a differential. It offers an impressive Rated Power of 800W and delivers a Rated Torque of 102.7Nm /57.9Nm, perfect for applications requiring reliable low-speed, high-torque operation. With a customizable operating voltage ranging from 24V to 48V and a low-noise design, it is engineered for long-lasting, low-maintenance performance.

The Future of Electric Drive is Precision Control

As the electric vehicle market matures, the demand for a more precise and efficient motor drive for electric vehicle applications will only increase. Our partners require not just power, but control—the ability to fine-tune energy consumption, maximize regenerative energy capture, and ensure a low noise signature for better operational environments.

The continuous evolution of power electronics allows us to push the boundaries of energy efficiency. The advanced control algorithms within a Rotontek system ensure that our motors operate at their peak efficiency, minimizing heat waste and extending battery life. By providing a scalable series of motor and transaxle combinations—from 150W low-power units to heavy-duty 20KW solutions—we ensure that our partners can select the optimal, ready-to-integrate system for any electric mobility platform.

Conclusion

The motor controller is truly the intelligence of the electric powertrain, and its quality dictates the vehicle’s success. By choosing Rotontek as your partner, you are securing a commitment to engineering excellence, optimized for the next generation of silent, powerful, and efficient electric vehicles.