Portable mobile devices are expected to move easily with users, operate across different locations, and deliver dependable performance. Achieving this level of mobility becomes difficult when designers must also keep the system light, compact, and energy-efficient. Delivering strong and stable power under these constraints requires specialized engineering. An advanced electric drive axle addresses this need by providing smooth and consistent motion without increasing overall weight or demanding excessive battery capacity.

Let’s explore the key requirements of portable mobile devices to understand how an electric drive axle is designed to meet them effectively.

Special Requirements for Portable Mobile Devices

1. Lightweight and Compact Design

Electric mobility devices must remain as lightweight as possible. A compact form factor keeps the device easy to carry, reduces user strain, and ensures it can fit into tight or irregular spaces. That is why engineers must optimize every part to maintain strength and performance while keeping the overall size and weight in check.

2. High Energy Efficiency and Long Battery Life

Most portable systems operate on limited battery capacity, which makes energy efficiency a central requirement. Efficient electrical and mechanical design reduces energy waste and helps users rely on the device throughout the day without frequent recharging.

3. Low Noise and Smooth Operation

Users expect the portable mobile devices to operate in a quiet and vibration-free manner. Low noise enhances user comfort and prevents disturbances, while smooth motion ensures safe handling, stable performance, and better control.

4. High Reliability and Durability

Portable devices operate across diverse terrains, temperatures, and usage patterns. They must withstand repeated movement, continuous vibration, and occasional impact without performance loss.

5. Ease of Integration and Adaptability

Since portable devices come in many shapes and sizes, the internal components must integrate easily into different configurations. Designers look for drive systems that fit multiple mounting positions, support various wheel sizes, and connect seamlessly with a range of controllers and batteries. High adaptability allows manufacturers to develop diverse mobility products without redesigning the entire system from the start.

Rotontek Ultra-Light Electric Drive Axle

The Rotontek ultra-light electric driving axle is engineered specifically for compact mobility applications. Let’s have a look at its top features:

1. Ultra-Light Design

Rotontek has reduced the overall weight of the drive axle to roughly 3 kilograms, which is remarkably low for a complete power transmission unit.

This streamlined structure allows manufacturers to build devices that remain easy to lift, maneuver, and transport.

The low weight also contributes directly to longer battery life since the drivetrain requires less energy to move the system.

2. Low Noise and Smooth Operation

The axle is built with refined mechanical tolerances and vibration-reducing components that support quiet performance even under continuous load.

3. High-Efficiency Brushless Motor

The electric drive axle uses a brushless DC motor available in 150 W, 250 W, and 300 W configurations. This motor design showcases several performance advantages, such as:

- Strong and stable torque output for reliable propulsion.

- Low electrical losses that keep energy demands minimal.

- Reduced heat generation, extending both motor and battery life.

4. Durable and Reliable Performance

Rotontek electric drive systems use high-quality materials and precision engineering to ensure the electric drive axle performs consistently across long-term use. The motor and gearbox are crafted to withstand repeated starts, variable loading conditions, and continuous low-speed operation without premature wear.

5. Easy Integration Across Device Types

This electric drive axle is designed for seamless integration across a wide range of portable mobility devices. It works with multiple motor controllers, supports DC input voltages between 24 and 48 volts, and can be paired with wheels of different sizes through a customizable output shaft.

The gearbox ratio is engineered for controlled low-speed motion, allowing manufacturers to build diverse products without redesigning the entire drive system each time.

Conclusion

The development of advanced portable mobility requires a careful balance between power and portability. As we have explored, the Rotontek Ultra-Light Electric Drive Axle is engineered from the ground up to resolve this core conflict. It directly addresses the five critical requirements of modern mobility: lightweight design, energy efficiency, smooth operation, enduring reliability, and effortless integration.

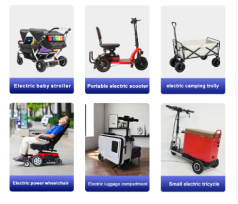

From enhancing the daily comfort of personal mobility aids to enabling the smart functionalities of autonomous luggage and service robots, our electric drive axle proves its versatility and robust performance across a wide spectrum of applications.

Contact us today to talk about your project requirements, request detailed specifications, or explore partnership opportunities. Let’s work together to build the next generation of lightweight, efficient, and high-performance mobile devices.

Related Product

Rotontek 150W / 250W / 300W Ultra-Light Small Brushless Low-Speed Drive Axle