Compared with the traditional brushed motors, BLDC motors have many merits. First, they use electronic commutation technology to avoid the wear of carbon brushes and commutators, reducing energy loss and improving work efficiency. Second, BLDC motors require only a little maintenance, have a longer service life, and reduce maintenance cost. With compact structure and light weight, BLDC motors have wide applications for locations where space is limited. Moreover, BLDC motors operate with very minimal levels of noise and vibration; hence, they are highly suitable for appliances that require low noise and high levels of precision in control, such as power tools, electrical vehicles, and high-precision machinery.

Higher Efficiency

BLDC motors are a great deal more efficient compared to conventional brushed motors. Also, traditional brushed motors have efficiencies that depend on wear in the carbon brushes and the commutator. Energy is wasted in power transmission, with a portion of the energy converted to heat that might cause overheating of a motor and reduce overall efficiency. Contrary to that, BLDC employs electronic commutation without carbon brushes and commutators to reduce the internal mechanical friction that smoothes the energy transfer and, hence, facilitates efficient conversion of electrical energy to mechanical energy.

Since BLDC motors operate on purely electronic commutation, an exact ECU is required to switch the direction of current in the windings, without fluctuations in current and energy losses from brush contact. This kind of electronic commutation will not only enable more energy efficiency but also allow more precision in motor control. Various studies relate that, generally, the efficiency achieved by BLDC motors has been more than 90%, whereas in brushed motors, the efficiency remains in the range of 70%-80%. The BLDC motors can maintain higher efficiency under varied loads. Because of this reason, many high-performance electrical devices would recommend their usage.

In applications like wind power generation, temperature regulation systems, and electric vehicles, the efficiency of a BLDC motor is quite high; this greatly cuts down on energy consumption and raises the bar for better performance of the system. This is especially so in an electric vehicle, which operates on limited battery power, wherein a high-efficiency BLDC motor will contribute to extending its driving range by a great deal.

Higher Efficiency

One of the major advantages of BLDC motors is that they can be maintained very easily. In conventional brushed motors, commutation is done by the contact of carbon brushes and commutators. The brushes wear out over time and have to be replaced periodically. This mechanical friction generates a lot of heat during motor operation besides affecting the long-term reliability of the motor because of the wear and tear on the brushes.

On the other hand, in the case of BLDC motors, this is a brushless design; it means no carbon brushes and commutators—no moving contacts inside the motor—are used; hence, mechanical wear can be reduced greatly. This brushless design makes BLDC motors require almost no regular maintenance. Besides, most of the electronic commutation systems in BLDC motors are adaptive—that is, the load and speed modify the commutation strategy to avoid excessive wear and unnecessary waste of energy found in conventional motors.

Since there are no carbon brushes in BLDC motors, it runs more smoothly, and the frictionally produced heat is reduced to a minimum, further enhancing motor stability and reliability. Hence, BLDC motors find extensive application in those fields where high reliability is demanded, such as wind turbines, medical devices, and drones that require operation for extended periods without the occurrence of frequent breakdowns or faults.

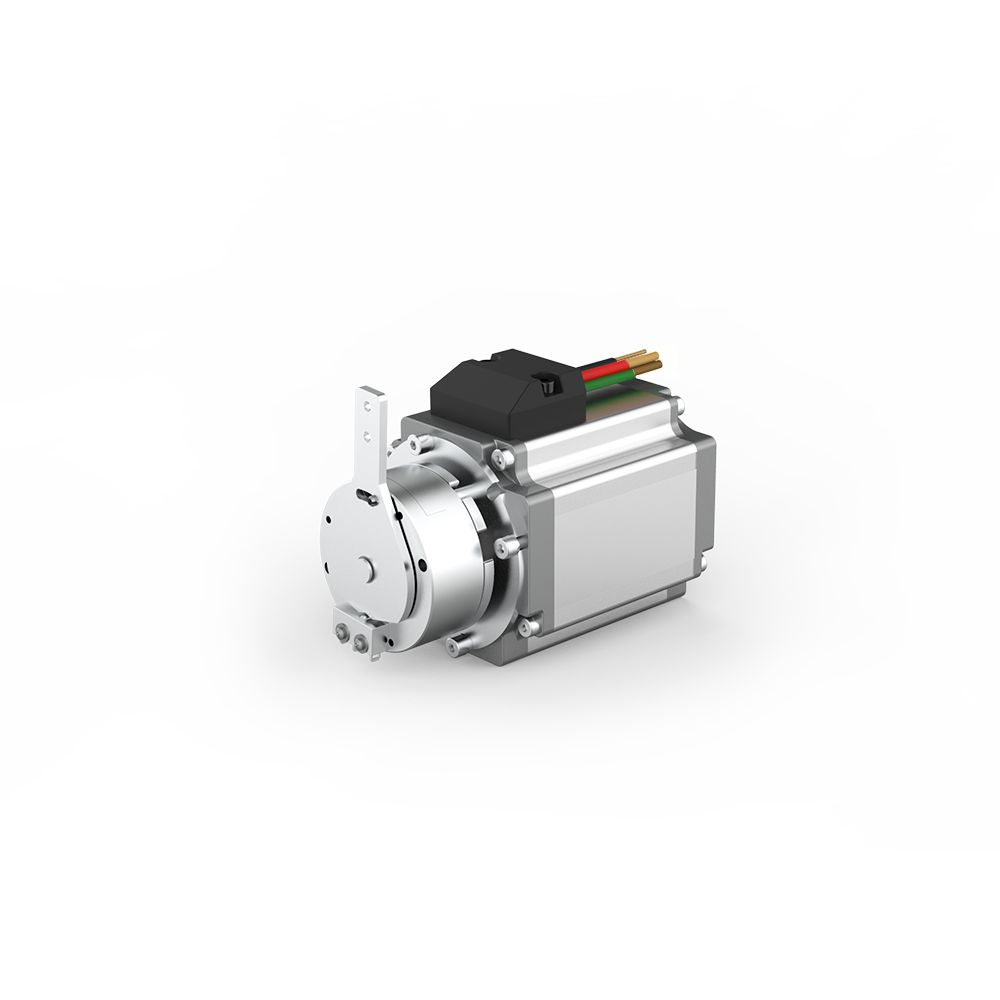

Compact Design

Other key advantages of the BLDC motors are in their compact design. Since there is no mechanical commutator, traditional motors can give the same or even higher output power in a smaller form factor. For the same required power, the BLDC motors are much smaller and lightweight compared to traditional motors by virtue of their higher power density. This makes BLDC motors highly valuable for applications with limited space.

Compact in size yet excellent in power density, BLDC motors can provide strong performance with their small and lightweight design for power tools, electric vehicles, and consumer electronics. In electric vehicles, for example, the compact design of the Rotontek it BLDC motors optimizes interior space in vehicles and allows for high space utilization of the battery, which further extends the driving range.

This compactness of the BLDC motors makes it even adaptable to different industrial usages in precision motion control in robotics. For some precision machineries or automation equipment, the small size of the BLDC motors allows more appropriate power transmission and its control in restricted spaces, optimizes not only the general design but also the performance of the particular equipment.

Precise Control

Among the salient features of a BLDC motor is its precision control capability. Since it employs electronic commutation technology, a BLDC motor is capable of precision control of the direction and magnitude of current in the windings via an advanced control unit that enables the motor to precisely control its speed and torque. Because of this electronic control, BLDC motors can have high precision, and they can also provide fast responsiveness when operating under various conditions.

Compared to the traditional motor, BLDC motors have more flexible speed and torque adjustment. When the load changes, the BLDC motors can adjust the input current immediately to operate smoothly. Especially at high speeds and large fluctuations in load, BLDC motors can maintain larger stability and avoid phenomena such as speed fluctuation or too small torque, which happens with traditional motors. Because it gives very precise control, the BLDC motors are widely applied in robotics, aerospace, automated production lines, and precision tools or instruments where high standards of controlling are needed.

Meanwhile, combined with advanced control systems, BLDC motors can also realize more complex motion patterns, such as high accuracy positioning and constant speed cruise. All those make BLDC motors the core component in loads of high-end equipment. In high-end industrial automation, BLDC motors can do some very complex tasks, such as precision cutting and assembly line transportation, all relying on their precise control capability.

Low Noise

Comparatively, BLDC motors obviously have an advantageous edge in noise control over traditional brushed motors. In the case of traditional brushed motors, friction between carbon brushes and the commutator generates significant noise. Normally, this noise will have a higher frequency that can break the quietness of the work environment. In contrast, because of the absence of contact parts such as brushes and commutators, mechanical friction in BLDC motors is much lesser, and hence noise from the motor during its operation is far less.

BLDC motors can operate with low noise both at low and high speeds due to their operational efficiency. The accurate electronic control system allows the motor to run smoothly without the variations of torque that characteristically raise noise in conventional motors during transition-in, acceleration, and deceleration. The quiet function makes BLDC motors suitable for silent places, such as offices, hospitals, and homes.

The low-noise characteristics of BLDC motors offer a better working environment for workers of industrial equipment and reduce health hazards resulting from noise pollution. Indeed, most modern industrial facilities use large numbers of BLDC motors for automated production lines and precision instruments in order to lower the overall noise levels in their equipment, hence improving the overall work efficiency and comfort of employees.

Better Durability

This is the other big positive for BLDC motors: their reliability. Since they have no carbon brushes or wear-prone parts, BLDC motors reduce friction and wear damage, further extending the service life of any motor. Traditional brushed motors have restricted lifespans for the carbon brushes, and the commutator wears out easily, which increases the possibility of the motor failing after being used for some time. By contrast, Rotontek it BLDC motors are designed for higher robustness, allowing them to support longer operation periods and more starts and stops.

BLDC motors have also proved to be durable by operating in extreme work conditions. Since they have simple structures with no parts that may easily wear out, they can bear high temperatures, humidity, and any form of extreme working environments. Most BLDC motors have quality materials and constructions for reliable operation in most high-temperature and humid environments; for long-term stability, they can bear operational temperature and humidity up to a certain level.

This excellent durability makes BLDC motors widely used in the fields of industrial automation, aerospace, medical equipment, and electric transportation, where the high reliability and durability of the motor are particularly important to guarantee stable system performance.

Eco-Friendly

The environmental benefits brought about by BLDC motors have gradually turned it into one of the most competitive advantages. Since Rotontek it BLDC motors are highly efficient, a lot of energy waste during operation can be avoided, and therefore, power consumption is comparatively low. For large-scale power-consuming industrial systems, saving energy consumption will not only save operating costs but also reduce carbon dioxide emissions and minimize negative environmental impact.

Combined with its brushless design, furthers the reduction in pollution resulting from carbon brush wear in BLDC motors. Since the motor is running, in ordinary motors, the carbon brushes may wear off with time and can cause harmful emissions into natural environments. Since BLDC motors do not have such wearing parts, such problems are avoided. Environmental friendliness on the part of BLDC motors makes them quite suitable for applications which involve strict environmental requirements, such as electric vehicles, wind power generation, and smart appliances.