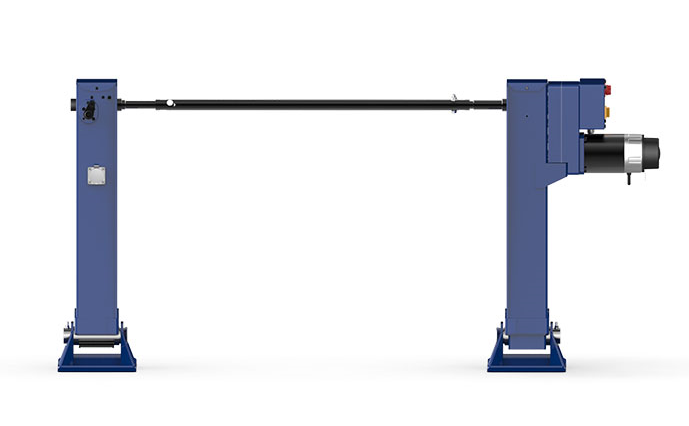

Drive motor

The motor of the electric outrigger of the truck is much more powerful than that of the RV. This thing has to withstand the brute force of a 30-ton heavy truck unloading its cargo with its body tilted, and it has to be as steady as an old dog in the mud. Now the mainstream is divided into two schools: brushed motors are cheap and durable, and brushless motors are precise and power-saving, just like the difference between manual and automatic transmissions.

The carbon brush of the brushed motor is a delicate bag. The mud and water mixture on the construction site can directly cut the life of the carbon brush in half. Last year, a fleet in Shandong replaced the inferior carbon brushes, and as a result, 8 of the 12 outriggers were burned during unloading. Experienced drivers all know that you have to use a motor with IP67 protection level, and the waterproof rubber ring should be as tight as a condom – don’t laugh, someone really did a comparative experiment with Durex.

The reduction box is the key to the burst of power. Although the efficiency of the worm gear structure is only 60%, the self-locking feature can save lives at critical moments. There is a counterintuitive design: after the outrigger is fully extended, the motor will rotate half a circle more, which is to offset the gap by pre-tightening the gear deformation. It’s like the last “click” sound when twisting the bottle cap. Without this design, the outrigger will shake like dancing.

Control system

The control system of the RV electric outrigger is much more pretentious than that of the truck. You have to take care of the millimeter-level leveling of the four outriggers at the same time, and you have to be careful of the slope of the camping site. Nowadays, high-end RVs all use dual control systems: the touch screen panel is used for show, and the physical buttons are kept for life. Last year, a popular RV changed the buttons to full touch control. As a result, the operation failed when wearing gloves in winter, and the owner almost flipped over on the snow slope.

The pressure sensor here plays permutations and combinations. The 16 sensors on the four legs will play “elimination” – automatically find the three most stable fulcrums, and the leg that is suspended is used for fine-tuning. This trick is learned from the tripod, but with a fool-proof design: if the ground is uneven, the system will reselect points like a hopscotch game.

The anti-overload mechanism is the real IQ tax disaster area. Don’t really push the 5-ton outriggers to 5 tons. Leaving 20% margin is an industry unwritten rule. A ruthless person found in actual testing that the protection mechanism of a certain brand of outriggers was activated at 4.8 tons, and it can actually carry another 1 ton – this is like an airbag, it is better to trigger it by mistake than to have an accident. Just like the overload protection of CNC machine tools, the set value is always 15% ahead of the nominal value.

Power module

The power heart of the electric landing gear is a schizophrenic. It must have continuous output like a power bank, but also have the awareness of explosion-proof devices. The mainstream now is the lithium battery + supercapacitor combination package, just like the off-road vehicle is equipped with double fuel tanks – lithium batteries are responsible for long-term flow, and capacitors are specialized in treating instantaneous large currents.

The battery management system is deeper than the ICU of a tertiary hospital. There are 48 temperature probes hidden in the 16-series and 24-parallel battery pack, which is denser than the thermometers in a hot pot restaurant. Last year, a copycat manufacturer cut corners and cut the number of probes in half, and as a result, the battery set off fireworks directly in the heat wave of Dubai Airport. The serious solution must use active balancing technology, just like equipping each battery unit with a private nutritionist.

Emergency power supply is the real black technology. After the main power supply is off, the supercapacitor can take over the power supply within 3 milliseconds-this speed is enough for you to blink one-tenth of your eyes. What’s even more amazing is the self-destruct fuse, which will melt into two pieces when it encounters a short circuit, just like a spy capsule.

Lifting mechanism

This mechanical system plays with the philosophy of combining rigidity and flexibility. The screw drive should be as precise as a Swiss Army knife, and the buffer device should learn to unload force like Tai Chi. Now high-end products all use planetary roller screws. Don’t be fooled by the mysterious name, it is actually turning the toothpick of the traditional screw into a mace – the contact area increases by 5 times, and the life span is directly doubled.

The self-locking mechanism is the life-saving trick. The electromagnetic brake must bite like a trap at the moment of power failure, and a delay of more than 10 milliseconds can cause a disaster. There is a counter-intuitive design: a greater driving force is required when descending, which is to prevent gravity acceleration from causing trouble. It’s the same as stepping on the brake when going down a steep slope, except that the motor is desperately rotating in the opposite direction.

Overload protection plays a psychological game. The nominal 10-ton landing gear can actually carry 15 tons, but the protection program will be activated if it exceeds 12 tons – this 20% margin is not due to poor technology, but a regret medicine for reckless people. Just like the feed force limit of CNC machine tools, it is obviously able to be tough, but it pretends to be weak. The ground staff of a certain airline company once tested a container as a counterweight, but after the protection was triggered, they thought the equipment was faulty, which made a big joke.

The voltage tolerance setting of the electric landing gear is comparable to walking on a tightrope. Lowering the threshold can protect the circuit but is easy to trigger by mistake, and raising it may burn components. Actual combat data shows that in the high salt fog environment in the coastal area, the voltage fluctuation threshold should be relaxed by 8%, and the thickness of the gold plating layer of the connector should be increased.

Sensor

This pile of electronic probes is the real “drama queen”. It is necessary to play the role of an honest man of the weighing sensor and take into account the gymnast attributes of the tilt sensor. Nowadays, high-end cargo planes are equipped with an eight-layer sensor array: 3 pressures + 2 angles + 1 vibration + 2 temperatures, which is three more than the five senses of the human body.

The vibration sensor plays a spy game. Use MEMS accelerometers to capture tiny vibrations of 0.01g. This sensitivity can detect the movement of the flight attendant pushing the food cart in the cabin. Last year, a cargo plane landed and the system alarmed. After disassembling it, it was found that two ball bearings inside the landing gear were broken – the vibration spectrum is more accurate than B-ultrasound.

Temperature compensation is the real black technology. Stainless steel will shorten by 0.2mm compared to normal temperature at minus 40℃, and the sensor must be able to do math problems by itself. Just like the thermal deformation compensation of five-axis machine tools, the landing gear sensor has a built-in material expansion coefficient database. The accident of the Antarctic expedition team was caused by a certain copycat sensor that misjudged the resistance change caused by low temperature as abnormal force.

Support structure

This pile of metal skeletons is playing a balancing act of “wanting both”. It has to be harder than Wolverine’s adamantium, but as soft as a cat’s paw. 7075-T6 aluminum alloy is the basic model, but the real tough ones use titanium alloy + carbon fiber woven layer – this configuration is comparable to the chassis of an F1 car, but the price can buy three BMW 7 Series.

The buffer is the magician of mechanics. The oil-gas mixed buffer must accurately control the CP value of nitrogen pressure and hydraulic oil viscosity, just like mixing a cocktail, you have to pay attention to the proportion. The unique skill of Boeing 787 is the two-stage buffer: the first 70% of the stroke is gentle like water, and the last 30% is suddenly hard-core, just like the experience of eating popping candy.