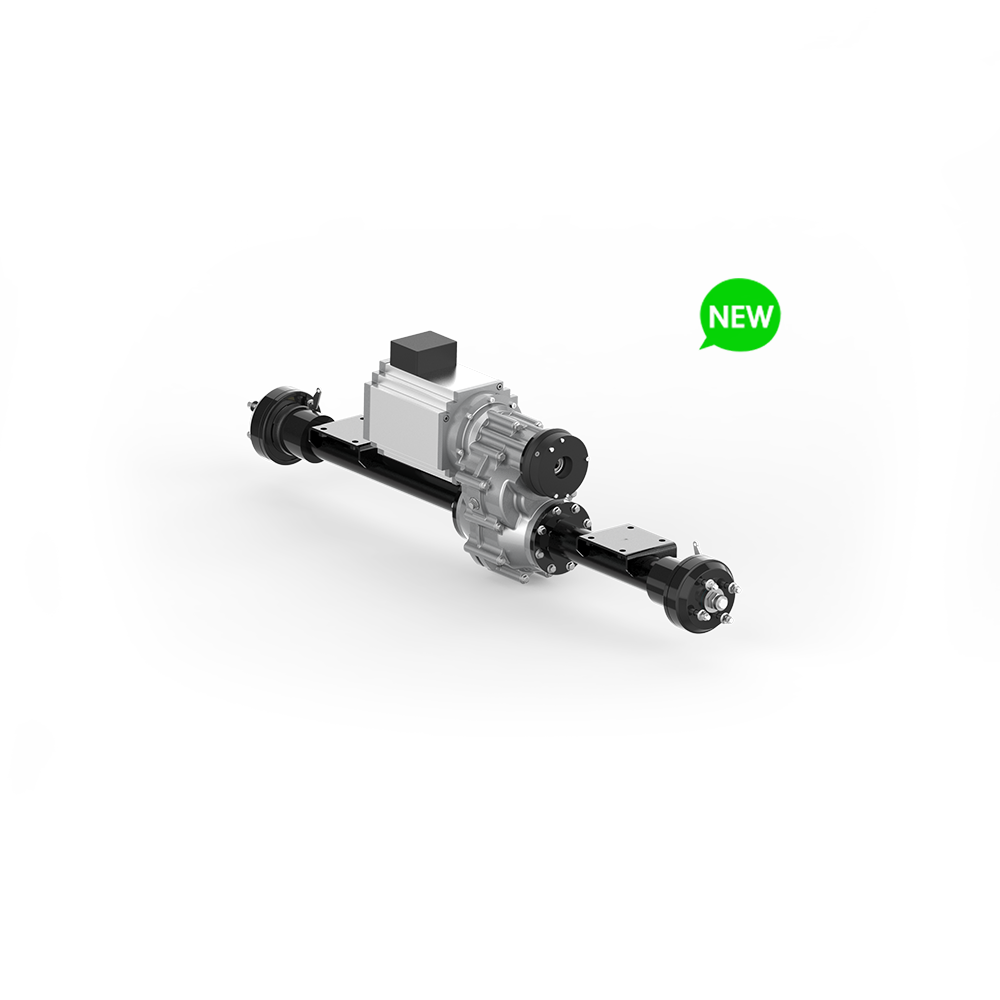

The primary components of an electric transaxle include the motor, gearbox, differential, and control module. The motor power typically ranges from 2 to 50 kilowatts, the gearbox transmission efficiency reaches up to 95%, the differential allows a speed difference of up to 50% between the left and right wheels, and the control module has a lifespan exceeding 50,000 hours.

Motor

An electric transaxle has a motor power of between, 2 kilowatts and 50 kilowatts depending on system design and application. The efficiency of high-efficiency motors is generally over 90%, and its energy loss is small, which can still provide enough power for the whole transmission system. The motor provides high torque as soon as it starts, and that is critical for making the system to react and to be stable. The motor’s response time typically is around 100 milliseconds, according to industry reports, and can satisfy changing load demands rapidly. This high performance gives the electric transaxle application capabilities for some of the most punishing working environments, ensuring reliable power transmission.

The motor should usually be designed with size and weight in mind to match well with everything else. The motor would weigh anywhere between 10 and 150 kilograms, depends on the application requirements and overall design constraints. Smaller motors make the whole system in which they enter lighter, and this contributes to increased efficiency and flexibility. The motor choice is directly relevant to transaxle performance. It is recommended to balance performance and cost for the selection of motor considering the high-power motors option, provide stronger power, However come with higher costs and energy consumption.

Gearbox

The gearbox is an important part in the electric transaxle, which adjusts the output speed and torque of motor to suit it to achieve higher efficiently. The transmission ratio of the gearbox ranges from 1:4 to 1:10, significantly lowering output speed relative to input speed of the motor; it is torque multiply. The total output torque is the highest at low speeds as a result of this design, which bestows the electric transaxle with strong driving force.The performance of the gearbox directly relates to energy loss in the whole system. Such gearboxes have a transmission efficiency that exceeds 95%, thus minimizing power losses from the engine to the wheels.

How the gearbox is structurally arranged and what material it is made ofDisney use will also be a very important point. The gearbox is mainly made of alloy steel as the main material, and after precision machining and heat treatment, the hardness and wear resistance of the gears are significantly improved, so that it can effectively work under high load and high speed for many years. Depending on the actual application, a different design specification may be established for the number of teeth, tooth shape, or module to meet the load requirements of the electric transaxle. High-specification gearboxes can have service lives in excess of 20,000 hours, thus reducing the frequency of maintenance and downtime.

Differential

In an electric transaxle, the differential is an important component that supports the speed difference of the two drive wheels on the left and right sides when making a turn, helping to quasi-stabilize the system/vehicle in a way that helps maintain controllability. The system would create wheel slip that could ultimately lead to loss of driving stability if a differential were missing. The differential inside the gearbox is very complicated and consists mainly of a planetary gear set and side gears. Those gears are typically heat-treated and manufactured of high-strength alloy steel, having their hardness over HRC60, which can not only improve the wear resistance but also the impact resistance enormously.

The differential is also a very mechanically-efficient way to achieve this. Standard differentials tend to be around 95–98 % efficient and basically, some power will always be lost in energy transfer. High efficiency differentials is of great significance to the long-term operation,which has a substantial impact on overall energy efficiency performance of the electric transaxle. Proper lubrication and maintenance of the differential can appropriately extend its service life and reduce the failure rate, which will help to reduce economic losses caused by machine stoppage.

Control Module

The control module is the electric transaxle “brain”, in charge of controlling the operation of the rest of the system. The Control Module takes in the motor power output, gearbox speed, as well the differential loads at all times to optimize the system performance under any load conditions. Many control modules can perform thousands of calculations per second, making it response to load changes within milliseconds and ensure smooth functioning of the transaxle. This means smoother torque output and more accurate speed control for the transmission system, among other benefits.

The power consumption of a control module generally adds up to a few W and often it reaches even several tens of W according to the type and configurations. Low-power designs help eliminate wasted energy and improve the efficiency of a system a key focus area for many manufacturers during development. The controlling module is not just regarding computer efficiency, yet when it relates to the long-term life of the transaxle additionally relies upon this relaxation. Common control modules offer an average life of more than 50,000 hours, ensuring that the system will keep working healthily under high-load conditions for a long time.