The basic principle of a hydraulic pump is to convert mechanical power into hydraulic energy, which involves creating flow and pressure within a hydraulic system. This conversion allows hydraulic pumps to generate enough power to overcome pressure induced by a load at the pump outlet.

Fundamentals of Hydraulic Pump Operation

Basic Mechanics of Hydraulic Pumps

Hydraulic pumps are pivotal in converting mechanical energy into hydraulic energy. They achieve this through the creation of a vacuum at the pump inlet, allowing atmospheric pressure to force liquid from the reservoir into the inlet line. The mechanical action of the pump then propels the liquid to the pump outlet and into the hydraulic system. This process involves intricate fluid dynamics, governed by principles like Pascal’s law, which states that pressure exerted anywhere in a confined fluid is transmitted equally in all directions.

Key components in this mechanism include the pump casing, which houses the moving parts, and the drive shaft, which initiates the mechanical motion. The importance of these components is paramount, with materials like stainless steel (Stainless Steel – Wikipedia) often used for their durability and resistance to corrosion.

Types of Hydraulic Pumps and Their Working Principles

Hydraulic pumps are classified into various types, each with unique working principles and specifications.

- Gear Pumps: Gear pumps, typically used in low to medium pressure applications, operate by meshing the gears in a tight enclosure. The simplicity in their design translates to cost-effectiveness and a notable power-to-size ratio. For instance, a standard gear pump might offer a pressure range of up to 250 bar and a maximum speed of 3000 rpm.

- Piston Pumps: Piston pumps are more complex and used in high-pressure applications. They work by moving cylinders (pistons) in a reciprocating motion within a cylindrical block. These pumps can handle pressures up to 700 bar and are favored for their efficiency and variable displacement capabilities.

- Vane Pumps: Vane pumps, known for their quiet operation, consist of a rotor with radial slots that house vanes. These vanes extend and retract, creating chambers for fluid movement. A typical vane pump can operate at pressures up to 180 bar, making them suitable for mid-range applications.

Each type of pump has its advantages and disadvantages. For example, gear pumps are known for their durability but may not be as efficient as piston pumps. Vane pumps offer smooth operation but can have limited pressure capabilities compared to piston pumps.

Select the hydraulic power unit

In selecting a hydraulic pump, factors like power, efficiency, cost, and application-specific requirements play a crucial role. Power ratings can vary significantly, with some industrial hydraulic pumps operating over 100 kW. Efficiency is another critical factor, as it directly impacts operational costs. High-efficiency pumps can lead to significant energy savings over time. The cost of these pumps is also a consideration, with prices ranging from a few hundred to several thousand dollars depending on the type, size, and specifications. Durability and material quality are crucial for ensuring a long lifespan, which can range from 5 to 10 years under proper maintenance.

When evaluating these pumps, it’s essential to consider the specific application requirements, such as the necessary pressure range, flow rate, and the nature of the fluid being pumped. For example, pumps used in heavy machinery require robust construction and high power ratings, while those in precision instruments might prioritize accuracy and efficiency.

Components of a Hydraulic Pump

Structure and Function of Key Components

A hydraulic pump comprises several crucial components, each playing a specific role in its operation:

- Pump Casing: The casing encloses and protects the internal components. It also channels the hydraulic fluid to and from the pump. The casing must withstand high pressure and is typically made of cast iron or stainless steel for strength and durability.

- Drive Shaft: This component transmits mechanical energy from the motor to the pump. It’s often made of hardened steel to endure the stresses of rotational forces.

- Gears, Pistons, or Vanes: Depending on the type of pump (gear, piston, or vane), these components are responsible for the actual pumping action. They move or rotate to create a flow of hydraulic fluid. Materials like steel or composite alloys are common for their wear resistance and longevity.

- Bearings and Bushings: These parts support the moving components, reducing friction and wear. They are often made of bronze or other low-friction materials.

- Seals and Gaskets: Essential for preventing leaks, these components maintain the pressure within the pump and keep contaminants out. Nitrile rubber or polytetrafluoroethylene (PTFE) are common choices due to their compatibility with hydraulic fluids and temperature resistance.

Material Selection for Durability and Efficiency

Selecting the right materials for each component is crucial for the pump’s performance and lifespan:

- Stainless Steel: Used for casings and shafts, stainless steel offers corrosion resistance and strength. It’s ideal for harsh environments or where the fluid may be corrosive.

- Hardened Steel: Commonly used for gears and pistons, hardened steel provides the necessary toughness and wear resistance for these high-stress components.

- Bronze and Composite Alloys: Bearings and bushings benefit from materials like bronze, which offer durability and reduced friction.

- Rubber and PTFE for Seals: These materials ensure a tight seal and resist degradation from hydraulic fluids.

The choice of materials directly impacts the pump’s efficiency, cost, and maintenance requirements. For instance, a pump with high-quality seals and bearings may have a higher initial cost but will offer better long-term reliability and reduced downtime, ultimately saving costs.

In terms of power and performance, the materials used can affect the pump’s maximum pressure capacity and efficiency. For example, a gear pump with precision-machined steel gears can handle pressures up to 250 bar and maintain good efficiency, translating to less energy consumption and lower operational costs.

Durability is also a critical factor, with well-chosen materials extending the pump’s lifespan. A typical hydraulic pump can last between 5 to 10 years, depending on usage and maintenance. Regular maintenance, including checking and replacing worn components, is essential for maximizing the pump’s lifespan.

In summary, understanding the structure and materials of a hydraulic pump is vital for anyone involved in selecting, operating, or maintaining these essential components in hydraulic systems. The right choices in design and materials can lead to optimal performance, efficiency, and cost savings.

Hydraulic Pump Dynamics

Fluid Dynamics in Hydraulic Pumps

Understanding fluid dynamics in hydraulic pumps involves examining how fluids move and behave under pressure within the pump. The main factors include flow velocity, pressure changes, and the impact of pump design on fluid movement.

- Flow Velocity: This refers to the speed at which the hydraulic fluid moves through the pump. The design of the pump (such as the size and shape of its components) directly influences this speed. For instance, in gear pumps, the teeth spacing and gear width determine the flow rate, which can range from a few liters per minute to hundreds, depending on the pump size and design.

- Pressure Changes: Hydraulic pumps create pressure by forcing fluid against a load. The pump’s efficiency relates to its ability to maintain consistent pressure with minimal energy loss. A piston pump, for example, can generate pressure up to 700 bar, making it suitable for high-pressure applications.

- Pump Design: The design of the pump, including its components and materials, affects the fluid dynamics. For instance, the clearance between the gears in a gear pump impacts the flow rate and pressure it can generate.

Energy Transfer and Efficiency Considerations

Energy transfer in hydraulic pumps is a critical aspect, as it determines the pump’s efficiency and overall performance.

- Mechanical to Hydraulic Energy Conversion: The pump converts mechanical energy from its drive shaft into hydraulic energy. The efficiency of this conversion depends on factors like the design of the pump and the quality of its components. A well-designed pump can have an efficiency rating of over 90%.

- Energy Losses: Energy losses in hydraulic pumps occur due to factors like friction, leakage, and turbulence. Minimizing these losses is crucial for efficient pump operation. For example, using high-quality seals and bearings reduces friction and leakage, enhancing efficiency.

- Efficiency Metrics: The overall efficiency of a hydraulic pump combines volumetric and mechanical efficiency. Volumetric efficiency relates to the pump’s ability to manage the flow rate without leakage, while mechanical efficiency concerns the conversion of mechanical energy to hydraulic energy without losses due to friction or other factors.

- Cost Implications: Efficient pumps save on energy costs. For instance, a pump operating at 75% efficiency as opposed to 90% can lead to significantly higher energy consumption, impacting the operational costs. The cost of a hydraulic pump, which can range from a few hundred to several thousand dollars, should also factor in its efficiency rating and expected lifespan.

In conclusion, understanding hydraulic pump dynamics, including fluid dynamics and energy transfer, is crucial for optimizing pump performance, efficiency, and cost-effectiveness. The design, materials, and maintenance practices play a vital role in achieving these objectives. Properly designed and maintained hydraulic pumps not only save on energy but also ensure reliable and long-lasting operation.

Types of Hydraulic Pumps

Gear Pumps: Structure and Function

Gear pumps are among the most common types of hydraulic pumps due to their simplicity, durability, and cost-effectiveness.

- Structure: A gear pump typically consists of two gears, a drive gear (connected to the motor) and a driven gear, enclosed within a tightly fitting casing. The gears interlock and rotate, creating a vacuum that draws fluid into the pump. As the gears continue to turn, they transport the fluid around the casing to the outlet where it’s discharged under pressure.

- Function: Gear pumps excel in constant-flow applications and are commonly used in automotive power steering, machinery lubrication, and hydraulic power systems. They operate efficiently at pressures up to 250 bar and can achieve flow rates from 1 to 150 liters per minute, depending on the size and design.

Piston Pumps: Design and Operation

Piston pumps are versatile and efficient, suitable for high-pressure applications.

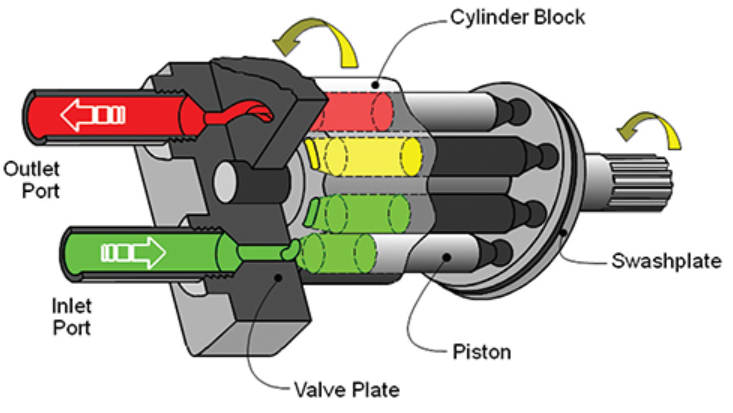

- Design: These pumps use a series of pistons in a cylindrical block. The pistons move back and forth in their cylinders, driven by a rotating swashplate or cam. This movement draws fluid into each cylinder on the inlet stroke and then forces it out under pressure on the outlet stroke.

- Operation: Piston pumps are known for their ability to handle high pressures, up to 700 bar, making them ideal for industrial and mobile hydraulics. They often come with variable displacement capabilities, allowing control over the flow rate and pressure. This adaptability makes them energy efficient, as they can adjust to the exact requirements of a given application.

Vane Pumps: Characteristics and Applications

Vane pumps are known for their quiet operation and are used in medium-pressure applications.

- Characteristics: Vane pumps consist of a rotor with several vanes, fitted in slots. This rotor is mounted off-center in a circular casing. As the rotor spins, the vanes slide in and out of the slots, maintaining contact with the casing walls. This creates chambers that increase in volume to draw in fluid, then decrease in volume to push the fluid out under pressure.

- Applications: Typical applications of vane pumps include automotive automatic transmissions, air conditioning systems, and low-noise industrial applications. They usually operate at pressures up to 180 bar and can achieve efficiency levels of around 85%.

In conclusion, selecting the right type of hydraulic pump depends on various factors like required pressure, flow rate, efficiency, cost, and application. Gear pumps offer simplicity and cost-effectiveness for low to medium pressure applications. Piston pumps provide versatility and high-pressure capability, ideal for demanding industrial uses. Vane pumps, with their quiet operation, are suited for medium-pressure applications where noise levels are a concern. Understanding these types, their structures, and functions helps in choosing the most appropriate hydraulic pump for specific needs and applications.

Hydraulic Pump Performance Metrics

Measuring Flow Rate and Pressure

Accurate measurement of flow rate and pressure is essential for evaluating the performance of a hydraulic pump.

- Flow Rate Measurement: Flow rate, typically measured in liters per minute (L/min) or gallons per minute (GPM), indicates the volume of fluid a pump can move per unit of time. Engineers use flow meters to measure this parameter. For instance, a gear pump in an industrial setting might deliver a flow rate ranging from 5 L/min to 150 L/min, depending on its size and design.

- Pressure Measurement: Pressure gauges measure the force the pump exerts on the hydraulic fluid, usually in bar or psi. This measurement is crucial for ensuring the pump meets the requirements of the hydraulic system it serves. For example, a piston pump used in a hydraulic press might need to generate pressures exceeding 400 bar to function effectively.

Assessing Efficiency and Power Output

Evaluating a hydraulic pump’s efficiency and power output is vital for determining its suitability for specific applications and its operational cost-effectiveness.

- Efficiency Assessment: Hydraulic pump efficiency combines volumetric and mechanical efficiencies. Volumetric efficiency pertains to the pump’s ability to minimize internal leakage and maintain a consistent flow rate. Mechanical efficiency relates to the conversion of mechanical energy into hydraulic energy. A high-efficiency pump, for example, might operate at 85% to 90% efficiency, translating to lower energy consumption and cost savings.

- Power Output Measurement: Power output, usually expressed in kilowatts (kW) or horsepower (HP), signifies the amount of work the pump can perform. It’s calculated based on the flow rate and pressure the pump generates. For instance, a pump with a flow rate of 100 L/min at 200 bar might have a power output of around 30 kW.

In conclusion, understanding and measuring hydraulic pump performance metrics like flow rate, pressure, efficiency, and power output is crucial for selecting the right pump for an application and for maintaining efficient and cost-effective operations. Regular monitoring of these metrics also aids in predictive maintenance, ensuring the longevity and reliability of the pump.

Common Applications of Hydraulic Pumps

Industrial Applications

Hydraulic pumps play a vital role in various industrial applications, driving machinery and systems that require high power and precise control.

- Manufacturing and Production Lines: In manufacturing environments, hydraulic pumps drive machinery like presses, conveyors, and injection molding machines. Their ability to provide controlled force and movement is crucial for precision tasks.

- Construction and Mining Equipment: Hydraulic pumps are integral to heavy-duty construction and mining equipment like excavators, bulldozers, and drill rigs. They provide the necessary power to handle tough tasks like digging, lifting, and drilling.

- Agricultural Machinery: In agriculture, hydraulic pumps power tractors, harvesters, and other farm machinery, enabling efficient cultivation, harvesting, and processing of crops.

Mobile Applications

In mobile applications, hydraulic pumps offer flexibility and portability, crucial for equipment used in various locations.

- Vehicle Systems: Hydraulic pumps are integral to many vehicle systems, including power steering, brake systems, and suspension systems. They ensure smooth operation and control, enhancing safety and performance.

- Mobile Hydraulic Tools: Tools like hydraulic jacks, cranes, and lifts rely on hydraulic pumps for their mobility and ease of use in different settings, from workshops to roadside assistance.

Role in Modern Machinery and Equipment

Hydraulic pumps are key components in modern machinery and equipment, contributing significantly to their performance and efficiency.

- Energy Efficiency: Modern hydraulic systems, including those powered by Rotontek pumps, prioritize energy efficiency. These systems are designed to deliver the necessary power while minimizing energy consumption, reducing operational costs.

- Precision and Control: The precision control offered by hydraulic pumps, such as those in Rotontek’s product line, is essential for applications requiring fine movements and adjustments, such as in robotic systems or precision manufacturing equipment.

- Durability and Reliability: Pumps from reputable manufacturers, including Rotontek, offer durability and reliability. Their construction enables them to withstand harsh conditions and continuous use. Choosing such pumps proves to be a wise investment for long-term operations due to their robust design and consistent performance.

In conclusion, hydraulic pumps are indispensable in various industries, from manufacturing to mobile applications. They provide the necessary power, control, and efficiency required in modern machinery and equipment. Brands like Rotontek offer innovative solutions that enhance these aspects, making them a recommended choice for high-quality hydraulic systems.