Hydraulic landing gears operate by using hydraulic oil to generate pressure, which drives the hydraulic cylinder for rapid lifting and lowering. They have high power density and can support over 30 tons of weight, but maintenance costs are high. Electric landing gears use electric motors and ball screw transmission, with an energy efficiency of up to 90%. They can operate normally in environments ranging from -40°C to 70°C and have low maintenance requirements.

Working Principle

Hydraulic landing gears rely on changes in hydraulic oil pressure to drive the hydraulic cylinder for lifting and lowering. The hydraulic pump pressurizes the hydraulic oil, which flows through the pipeline into the hydraulic cylinder, pushing the piston rod to perform linear motion, thereby driving the landing gear up and down. The hydraulic oil used in hydraulic systems typically has characteristics such as stable viscosity, high-temperature resistance, and oxidation resistance to cope with high pressure and high-temperature working environments.

Hydraulic landing gears have high power density characteristics. For the same volume, a hydraulic system can generate 2-3 times more output force than a mechanical system. For example, a hydraulic landing gear with a rated load of 30 tons typically has a hydraulic cylinder diameter of 150-200 millimeters and a working stroke of more than 500 millimeters. With such a design, the landing gear can complete the entire lifting process within 10 seconds, making it irreplaceable in large-scale equipment in terms of speed and power output.

Compared with hydraulic ones, an electric landing gear would use an electric motor as the power source. Using an electric actuator or a form of transmission mechanism-such as a ball screw-to convert the motor’s rotational motion to linear, the landing gear drives the mechanism to lift and lower. In general, AC or DC motors are employed as the driving source in such electric systems. The electric landing gears in Rotontek are powered by a 24V DC motor, which, at very low power consumption, is capable of providing a single leveling load of 10 tons, a dual-leveling load of 20 tons, and a four-leveling load of 40 tons.

Their advantage over hydraulic landing gears is that electric landing gears are responsive and easy to control. In fact, by controlling the speed and direction of a motor, precise adjustments in landing gear can be realized. Besides this, electric systems usually include sensors that enable real-time monitoring of motor speed, output torque, and even position feedback, thus further improving the precision of control as a whole. In such a design, an electric landing gear can keep constant output force while the height adjustment precision keeps within ±0.5 millimeters.

Structure and Composition

The basic components include hydraulic pumps, hydraulic cylinders, hydraulic pipelines, valves, and an oil reservoir. Although the general concept of the hydraulic system seems pretty simple, its main complexity lies in the design of the pipeline and the flow control of the liquid. Hydraulic oil circulates in the system, entering the hydraulic cylinder through the course of different valves, controlling the movement of the landing gear. In most cases, hydraulic landing gears are fitted with accumulators and overflow valves that release excess pressure in case of system failure or very high pressure, thus keeping the system safe.

A pair of hydraulic landing gears for a 20-ton-load would have a hydraulic cylinder diameter of about 100 millimeters, and hydraulic oil flowing at 10-15 liters/minute gives the stroke of 200 millimeters in 5-7 seconds, satisfying the requirements of quick lift and descent for most equipment.

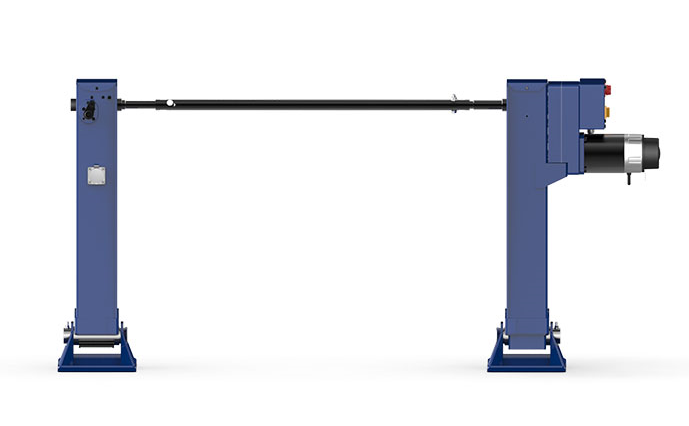

The major components of electric landing gears consist of an electric motor, a transmission mechanism such as a ball screw, a control module, and a power system. Electric landing gears do not rely on liquid media; hence, oil tanks, hydraulic pipelines, and other auxiliary components are not required, as compared with hydraulic systems. This is attributed to an efficient ball screw design in the Rotontek electric landing gear that converts the output torque of the motor directly into a support force. This makes for a more compact and lighter structure.

Performance and Efficiency

The performance of hydraulic landing gears is mainly reflected in their high power density and fast response capability. Because hydraulic oil is incompressible, a hydraulic system can provide immense output force in a very short time. A hydraulic system working at 3000 psi can easily reach a force output of 20.68 kilograms per square centimeter, which means that a hydraulic cylinder with an area of 100 square centimeters can provide a thrust of 20 tons.

Hydraulic systems operating over long periods may be affected by variable temperature and pressure conditions. The viscosity of hydraulic oil changes with temperature. If the ambient temperature falls below -20°C, hydraulic oil starts having a much higher viscosity, which adversely reduces system efficiency and slows down operational response. This is a serious drawback of using hydraulic systems in cold regions. Also, due to multiple friction points and flow resistance in the hydraulic system, the energy efficiency of hydraulic landing gears is normally in the range of 60%-70%.

Electric landing gears have higher energy efficiency, normally up to 80%-90%. One of the major advantages of an electric system is that it is insensitive to temperature, and for ambient temperatures ranging from -40°C to 70°C, it works normally. They also have a start-stop response time of less than 0.5 seconds, allowing flexible operations and precise positioning of the landing gear.

Reliability and Maintenance

While hydraulic landing gears are failure-prone, their failure points are mainly concentrated in hydraulic pumps, pipelines, and valves. It is evident that hydraulic systems operate under high pressure, and hence potential failure areas are within the pipes and valves owing to wear or leakage. During high-pressure working scenarios, the average annual leakage rate of hydraulic systems is about 5%, requiring refilling and replacement of hydraulic oil each year; further, sealing tests for the pipes are also required. Industry data shows that hydraulic landing gears have an average maintenance cycle of once every 1,000 hours, and maintenance costs are around 2-3 times higher than those of electric ones.

Compared with hydraulic landing gears, electric landing gears have relatively lower maintenance requirements. Statistics from actual applications show that the average maintenance cycle for electric landing gears can be extended to once every 3,000 hours, with the main maintenance involving checking motor connections and lubricating the transmission mechanism. Since no liquid medium is used, the electric landing gear has almost no risk of leakage, and the overall failure rate is below 1%.