As a supplier, we understand the importance of clarifying the distinct roles of components in an electric vehicle. A common question we encounter is why a Vehicle Control Unit (VCU) is necessary alongside individual controllers. This explanation helps you make informed decisions about your vehicle’s architecture, ensuring you select the right components for optimal performance and integration. Understanding this hierarchy is key to building a reliable and efficient electric vehicle system.

Vehicle Command and Control Hub

The Vehicle Control Unit (VCU) acts as the central brain of the electric vehicle, a role distinct from the more specialized functions of individual controllers. While a dedicated motor controller manages the precise torque and speed of the electric motor, the VCU oversees the entire vehicle’s operation. It processes inputs from the driver, such as accelerator and brake pedal positions, and translates these commands into coordinated actions for various subsystems. The VCU also continuously monitors vehicle states, including speed and battery levels, to make high-level decisions for safety, efficiency, and performance. It is the master coordinator that ensures all components work in harmony, which is a function beyond the scope of a single vehicle control unit that focuses on a specific domain. This centralized intelligence is crucial for complex functionalities like regenerative braking coordination and thermal management.

System Coordination and Supervision

The primary purpose of the VCU is to coordinate and supervise the various electronic systems that a standalone controller cannot manage. An individual motor speed controller is excellent at its specific task but operates in isolation. The VCU integrates this controller with the Battery Management System (BMS), the charger, the thermal management system, and auxiliary units. It ensures that energy flow is optimized between the battery and the motor, manages power limits for component protection, and implements vehicle-wide strategies for range extension. For instance, it can decide to reduce motor power if the battery temperature is too high, a decision that requires a holistic view of the vehicle’s status. This system-level supervision prevents conflicts and ensures smooth, reliable, and safe vehicle operation under all conditions.

Controller Communication and Data Management

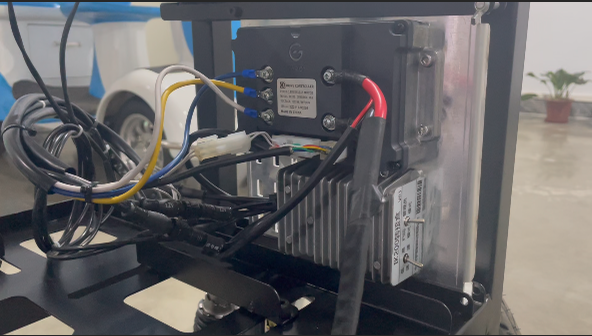

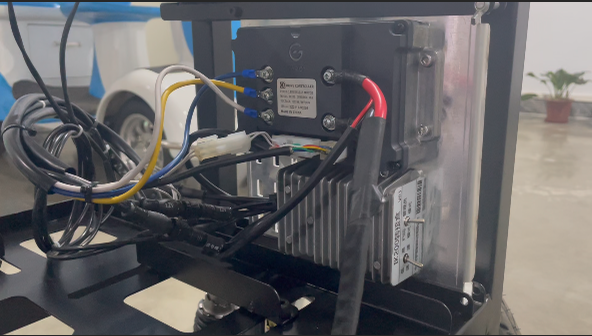

A critical purpose of the VCU is to manage communication and data flow between the various controllers and sensors throughout the vehicle. In a modern EV, numerous Electronic Control Units (ECUs) and controllers need to exchange information seamlessly over networks like the CAN bus. The VCU serves as the gateway and hub for this communication, interpreting data from one system and relaying necessary commands or information to others. It also aggregates vast amounts of operational data for diagnostics, logging, and providing information to the driver via the instrument cluster. This centralized data management simplifies the vehicle’s electrical architecture and is essential for advanced features like over-the-air updates and predictive maintenance, which individual controllers are not designed to handle independently.

Conclusion

While controllers are the powerhouse of the drivetrain, the VCU provides the necessary intelligence for modern EVs. At Rotontek, we design our motor controllers to integrate seamlessly with standard VCU architectures, ensuring reliable performance in specialized vehicles like forklifts and AGVs.