In the fast-paced industrial handling sector, power driving kits have transformed from mere auxiliary tools into indispensable assets. They are pivotal in boosting operational efficiency and reducing labor costs. By streamlining the movement of goods, these kits alleviate physical strain on workers and help prevent delays in production and logistics.

Enterprises and operators in this field frequently face a wide variety of weight-handling tasks. Given this diversity, a critical question consumers often ask when selecting a kit is: “What motor power should I choose?” This decision is crucial, as it directly determines the kit’s performance, efficiency, and overall cost-effectiveness in its intended application.

Understanding Motor Power

Before determining the suitable motor power for your power driving kit, it is essential to understand what power means and how it relates to torque.

1. Definition of Motor Power

The motor power of a power driving kit refers to the rate at which the motor converts electrical energy into mechanical energy. Expressed in watts (W) or kilowatts (kW), where 1 kW equals 1,000 W. This rating denotes the motor’s capacity to perform work over a given time.

2. The Relationship Between Power and Torque

Torque (τ) is the rotational force applied at a distance from a pivot point. Power (P) is the rate at which work is done. The core relationship between them is defined by the formula:

P = τ × ω

Where power (P) is measured in watts (W), torque (τ) in newton-meters (N·m), and angular velocity (ω) in radians per second (rad/s), this equation shows that power is the product of torque and speed. To increase power, you must increase either torque, speed, or both.

In practical applications, motor speed is often given in revolutions per minute (RPM) rather than rad/s. Therefore, the formula is commonly adapted for ease of use. The relationship between power (P), torque (T), and rotational speed (n in RPM) is:

P = (2π × n × T) / 60

This formula clearly demonstrates that for a given rotational speed (n), an increase in power necessitates a proportional increase in torque. This means a higher-powered motor in your power driving kit can generate greater torque, making it more capable of starting heavy loads from rest and overcoming resistance during movement.

3. Core Advantages of High-Power Motors

Valued at USD 197.78 billion in 2024, the global electric motor market is forecast to expand to USD 322.08 billion by 2030. A key driver of this growth is the superior performance these motors deliver in applications like industrial handling. Let’s explore their core advantages:

- Superior Heavy-Load Starting Capability: A high-power DC motor delivers high starting torque, providing the immense force needed to overcome inertia and resistance. Therefore, it’s ideal for setting heavy equipment in motion and handling large industrial loads.

- Enhanced Gradeability: High-torque motors supply the necessary power for industrial equipment to climb slopes effortlessly. They generate sufficient force at the wheels to effectively counter gravity, ensuring reliable performance on steep inclines.

- Consistent Speed Under Load:High-power motors, especially synchronous types, maintain a near-constant speed even under heavy loads. This guarantees consistent performance, prevents slowdowns, and keeps optimal material handling efficiency.

4. The Relationship Between Power and Efficiency

Motor efficiency, expressed as a percentage, is the ratio of useful mechanical output power to electrical input power. Selecting the correct motor power is critical for maximizing efficiency, as both underpowered and overpowered motors perform suboptimally.

An underpowered motor is forced to operate near its maximum capacity, which leads to excessive current draw, overheating, and an increased risk of failure. Conversely, an overpowered unit frequently runs at a low load factor, meaning a significant portion of input energy is wasted as heat. Additionally, overpowered models are physically larger and heavier, resulting in increased overall weight and size of the power driving kit.

Key Factors in Motor Power Selection

1. Load Requirement and Power Match

Start by assessing the load requirements and power match of your equipment. For that, get an idea of the necessary force required to start, accelerate, and run the machinery. Make sure the motor you choose actively meets and even exceeds the load demands of the intended applications.

2. Environment and Terrain Considerations

Pay attention to the motor’s operating conditions, including humidity, temperature, and dust levels. Also, look at the terrain as various sites need different motor power and efficiency. Here’s an overview:

- Flat Indoor Sites: For flat indoor spaces such as industrial warehouses, standard motor power is sufficient as conditions are controlled.

- Slight Slopes:If you are taking the equipment on slopes, you should get at least 15% to 20% more power to compensate for the extra effort needed to move against gravity.

- Outdoors or Uneven Surfaces:However, for extremely bumpy surfaces, you should get 25% to 30% additional power margin.

3. Speed Requirements

Motor power selection also depends upon the speed at which the equipment needs to operate. High-speed applications require motors that can sustain high RPM without compromising on torque, while low-speed equipment demands more torque than RPM.

4. Duty Cycle

Consider whether the motor will run continuously for a long time or intermittently for short periods. Based on that, you can choose a motor without worrying about overheating or premature wear.

5. Battery Compatibility

If the power driving kit is battery-driven, you should choose a motor that’s compatible with the battery’s voltage, capacity, and discharge rate. Otherwise, you’ll come across slowed performances and overall downtime.

Common Misconceptions and Tips

Several common misconceptions can lead to the poor selection of an electric drive kit. Let’s clarify them and review some key tips.

Misconception 1: Higher Power Means Higher Speed

In reality, speed is determined by the interplay of power and torque, as well as the machine’s design. A high-power motor with low torque will not necessarily achieve a high operational speed.

Misconception 2: The Highest Power Option is Always the Best Choice

It’s natural to opt for the highest motor power, but it’s not always the right choice. The correct approach is to carefully assess your application’s needs and select a motor whose specifications closely align with those requirements, avoiding unnecessary excess power.

Tip 1: Prioritize Torque for Demanding Applications

Do not focus on power ratings alone. For applications involving slopes, uneven terrain, or heavy loads, torque is the critical metric. It directly indicates the motor’s ability to deliver the force needed to overcome resistance and perform the work.

Tip 2: When in Doubt, Opt for a Margin of Safety

If you are uncertain about the exact power requirements, it is wiser to select a power driving kit with a slightly higher power rating. This provides a safety buffer that prevents overloading, ensures reliability, and extends the motor’s lifespan.

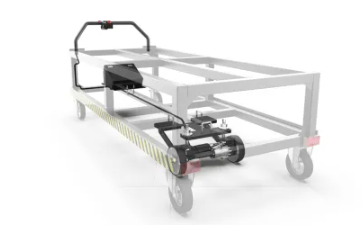

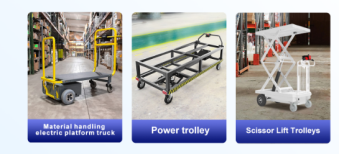

Choose the Power Driving Kit from Rotontek

When looking for a power driving kit that adapts to diverse industrial handling needs and aligns perfectly with the motor power selection principles discussed earlier, our Rotontek Power Trolley Kit, with its high-power brushless DC motor, stands out as the optimal choice. Engineered for versatility and peak performance, it offers a wide range of power options from 150W to 5000W. This extensive range ensures comprehensive coverage for the load, speed, and environmental demands of most industrial scenarios, eliminating the hassle of power mismatch for users. So why wait? Get in touch with us today!

Reference

[1]. Available at: https://share.google/UM7va32xmBGaUxjci