A power drive unit, often referred to as a power-assist system, integrates an electric motor to support human operation. Its core value lies in reducing the intensity of manual work, improving efficiency, and enabling smooth human-machine collaboration. In industrial and commercial applications, such systems not only enhance productivity but also protect operators from unnecessary physical strain.

However, while performance and durability are critical, noise reduction is equally important. Quiet operation fosters a calmer work environment, lower operator fatigue, and enhances focus by eliminating disruptive noise.

So, how does the noise level of power drive assembly operations influence the quality of the work? Let’s find out.

The Negative Impacts of Noise

The negative impacts of noise from a power drive unit are multi-layered:

1. For Human Health

(1) Hearing Damage

If a power drive unit generates excessive noise, it can irreversibly damage the human auditory system. The inner ear contains a large number of hair cells responsible for converting sound signals into neural signals and transmitting them to the brain. Loud noise can harm these hair cells. In the early stages, this may manifest as temporary hearing loss, where hearing can partially recover after resting away from the noisy environment. However, in severe cases, it can even result in complete deafness.

(2) Mental Fatigue

Noise is a significant factor contributing to mental fatigue. When the electric drive kit emits continuous or intermittent noise, it constantly stimulates the human nervous system, keeping the brain in a state of tension. Over time, this makes operators prone to tiredness, drowsiness, and lack of concentration. This not only reduces work efficiency but also raises the risk of workplace accidents.

(3) Communication Barriers

In a noisy work environment, even a simple instruction exchange becomes difficult. Operators must frequently raise their voices and repeat shouts, which increases communication challenges and decreases efficiency. In emergency situations, noise can mask critical safety information, directly elevating the risk level at the worksite.

2. For the Working Environment

(1) Environmental Pollution

In industrial areas, the simultaneous operation of numerous power drive units emitting high-intensity noise can create extensive noise pollution zones. Such pollution not only disrupts the normal work and daily lives of on-site employees but also extends to surrounding residential communities, adversely affecting the quality of life for residents.

(2) Industry Restrictions and Compliance Challenges

Different industries have stringent noise emission standards and regulations. Utilizing power drive units that fail to meet relevant noise standards may result in industry-specific restrictions and compliance issues. For instance, medical facilities, including hospitals, patient wards, and laboratories, require exceptionally quiet environments to facilitate patient recovery and ensure the accurate operation of sensitive instruments.

3. For Equipment

Generally, a loud noise is not an indicator of strong power. On the contrary, excessive noise may be a sign of design flaws, poor manufacturing processes, or substandard components. Gear noise may indicate insufficient material strength, inadequate heat treatment, or defective meshing design. Overall rumbling suggests insufficient structural rigidity, a lack of vibration-damping measures, and imprecise assembly techniques.

Sources of Noise in Electric Power Drive Units

Specifically, noise generated by a power-assist system can be attributed to three primary sources:

1. Mechanical Noise

Itis the primary noise of a power drive unit, originating from the gears meshing together. Continuous friction between moving components generates impact and vibration, which can be exacerbated by misalignment or inadequate lubrication. Furthermore, these vibrations propagate through the structural frame, inducing resonance that amplifies overall mechanical noise.

2. Electromagnetic Noise

This type of noise results from fluctuations in the motor’s magnetic field. Variations in magnetic forces within the motor cause vibrations and high-frequency whistling, which are particularly noticeable in low-quality motors or systems with poor control strategies.

3. Aerodynamic Noise

Aerodynamic noise stems from the airflow generated by cooling fans that prevent motor overheating. Although typically a secondary noise source, it becomes significant if the fan blades are poorly designed or unbalanced, producing a distinctive wind-like sound that contributes to the overall noise level of the unit.

How Rotontek Achieves Low-noise Operation

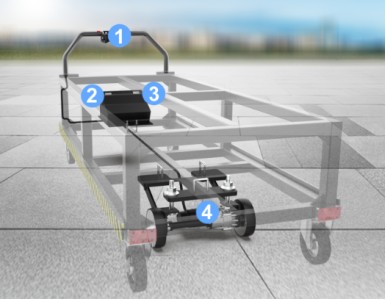

To effectively tackle the noise challenges in electric drive systems, Rotontek employs targeted advanced engineering solutions that address each noise source at its root. Our low-noise Low noise power trolley kit is made possible through several key innovations in design and technology:

1. High-Quality Materials and Precision Manufacturing

The core transmission components utilize high-strength forged alloy steel gears, precision-machined with fine tooth grinding technology. This process delivers an exceptionally smooth gear meshing surface and a highly accurate tooth profile, ensuring near-perfect engagement. As a result, gear-induced impact, friction, and vibration are significantly minimized, reducing mechanical noise to a minimum.

2. Powerful Brushless Motor

The system incorporates a proprietary high-performance brushless DC (BLDC) motor. Through in-depth optimization of the magnetic circuit, silicon steel material, and rotor dynamic balance, we substantiallyreducethe sources of electromagnetic noise at the physical level. This guarantees exceptionally smooth and highly efficient motor operation.

3. AdvancedMotor Control

The intelligent controller accurately and smoothly regulates the motor’s three-phase current output, enabling perfectly linear acceleration and deceleration. This advanced control strategy completely eliminates torque fluctuations and high-frequency whistling noise caused by irregular commutation and unstable current control.

4. Application

Currently, our low-noise electric power-assisted system is widely used in various fields, including hospital trolleys, logistics handling equipment, industrial electric vehicles, and hotel facilities. It is particularly worth mentioning that this power drive kit has garnered strong approval from a well-known Indian material handling equipment manufacturer. The company has integrated the kit into products and has highly praised its exceptional quiet operation and reliable performance.

Conclusion

Noise in a power drive unit is a critical factor that extends beyond mere comfort, impacting human health, environmental quality, and equipment reliability. Rotontek effectively addresses this challenge through precision engineering, a high-performance brushless motor, and an intelligent controller. As a result, users benefit from exceptionally quiet and efficient operation, enabling a more human-centric, modern, and compliant operational ecosystem.