In an increasingly automated and electrified world, noise is more than just a distraction—it’s a measurable indicator of wasted energy, poor design, and reduced operator comfort. For manufacturers and OEMs in sectors like material handling, medical mobility, and automated logistics, the demand for silent, high-performance drive solutions has never been higher.

At Rotontek, our engineering philosophy is built on delivering high torque and high efficiency with an absolute minimum of acoustic output. The question, “What makes a motor quiet?” drives our design process and is key to understanding the superior performance of our specialized drive series. A truly quiet motor is a masterpiece of precision engineering, addressing three primary sources of noise: mechanical, electromagnetic, and aerodynamic. This holistic approach is why we’ve earned a reputation as a trusted gear motor manufacturer.

Understanding the Sources of Motor Noise

Noise in any electric motor system originates from vibration, which then radiates sound waves. By isolating and minimizing these vibrations at the design stage, we can achieve the exceptional quietness that defines our product lines.

1. Mechanical Noise: The Challenge of Friction and Contact

Mechanical noise is arguably the most complex source to eliminate, especially in gear-driven systems. It arises from the physical interaction of moving parts:

Bearings: Poorly fitted or low-quality bearings can generate rattling, buzzing, or whining sounds. Our motors utilize preloaded bearings with minimal internal clearance, which virtually eliminates the ball-rattling noise and ensures each rolling element follows the same path, resulting in smoother operation.

Gears: The meshing of gear teeth is a significant source of noise in any low noise gear motor. When traditional spur gears engage, the force is transmitted abruptly. To counter this, Rotontek utilizes forged alloy steel gears with precision fine tooth grinding. This high-precision processing ensures the surfaces are smooth, and the pitch accuracy is maximized. In many of our assemblies, like the transaxle series, we employ special tooth patterns, such as helical teeth, which allow the teeth to mesh gradually. This gradual engagement results in a smoother, continuous transfer of force, significantly reducing impact noise and vibration.

Assembly and Alignment: Loose components, or misalignment between the motor and the gearbox, can cause structural vibrations. We utilize high-precision casings and standardized, rigid production processes to ensure a secure, perfectly concentric fit between all components, preventing the structure itself from acting like a loudspeaker.

2. Electromagnetic Noise: The Vibration of the Core

Magnetic forces are inherent to the operation of an electric motor, but when unbalanced, they generate noise. This electromagnetic noise, often heard as a high-pitched hum or buzz, is caused by the attraction and repulsion forces within the stator and rotor structure:

Cogging Torque and Torque Ripple: The interaction between the magnetic poles and the stator teeth causes variations in torque as the motor rotates, known as cogging torque and torque ripple. These variations create vibration. We mitigate this through advanced design techniques, including:

Optimal Slot/Pole Combinations: Selecting fractional slot/pole combinations that minimize the variation in magnetic reluctance.

Skewing: By skewing the stator slots or the magnets, the magnetic force is distributed more evenly across the rotational path, effectively smoothing out the ripple and reducing vibration.

Air Gap Uniformity: An uneven air gap between the rotor and stator creates unbalanced magnetic forces, which can deform the components and cause a buzzing noise. Precision manufacturing ensures the air gap is maintained with exceptional uniformity.

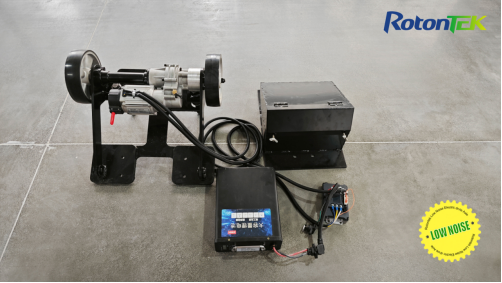

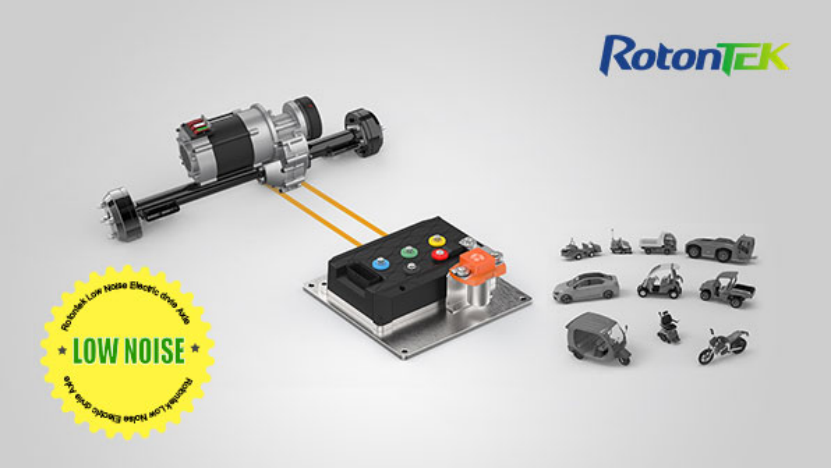

Rotontek’s Integrated Noise Reduction Series: The Power of Design

As a specialized gear motor manufacturer, we address the need for quiet power not with a single feature, but with a complete series of integrated drive solutions.

The LD62 Series, which includes models in the 3000W-5000W range, exemplifies what a modern, low noise gear motor can achieve.

Noise Specification: The LD62 series maintains a noise level restrained to ≤ 54 dB, a level comparable to a quiet office or household refrigerator—significantly below the noise threshold of traditional drive systems.

Precision and Power: This series uses high-precision, alloy steel hard tooth surface gears, ensuring durable and robust performance while maintaining the quiet operation required for applications like electric golf carts, intelligent logistics vehicles, and cleaning machines.

Integrated Safety: Furthermore, these units often incorporate an Electromagnetic Intelligent Brake System, which provides reliable, responsive stopping power without adding mechanical friction noise. The unit is designed with a high protection level, such as IP55, making it dustproof and waterproof for reliable long-term outdoor use.

3. Aerodynamic Noise: Quieter Cooling

Aerodynamic noise, is generated by the cooling fan and the turbulence of air flowing around the high-speed rotating components. While often less of a factor in fully enclosed systems, it must still be addressed:

Fan Optimization: In applications where a fan is required, the design of the fan blades is optimized to reduce air turbulence and minimize the siren effect that can occur at high speeds.

Enclosure Design: Our fully enclosed motor designs, particularly the integrated electric transaxles, inherently minimize aerodynamic noise by eliminating the need for complex, air-moving cooling structures that often contribute to turbulence.

The Advantage of Rotontek Precision

The relentless focus on reducing vibration and noise is fundamental to the value we provide our customers. A quieter motor is a more efficient motor, as noise is simply energy that has been converted into wasted acoustic waves. By investing in design optimization, superior materials, and high-precision manufacturing processes, we ensure that every Rotontek product delivers maximum power with minimum acoustic pollution.

Our integrated approach—addressing mechanical gear noise, electromagnetic force balance, and aerodynamic flow—allows us to consistently deliver a low noise gear motor that enhances the operator experience, meets strict regulatory standards, and provides a tangible competitive advantage for equipment built by our partners. This commitment to engineering intelligence is what drives our brand and continues to position Rotontek as a leader in the industrial electric motion field.