Transaxle Market Overview

Electric Dollys Market Using Electric Transaxle

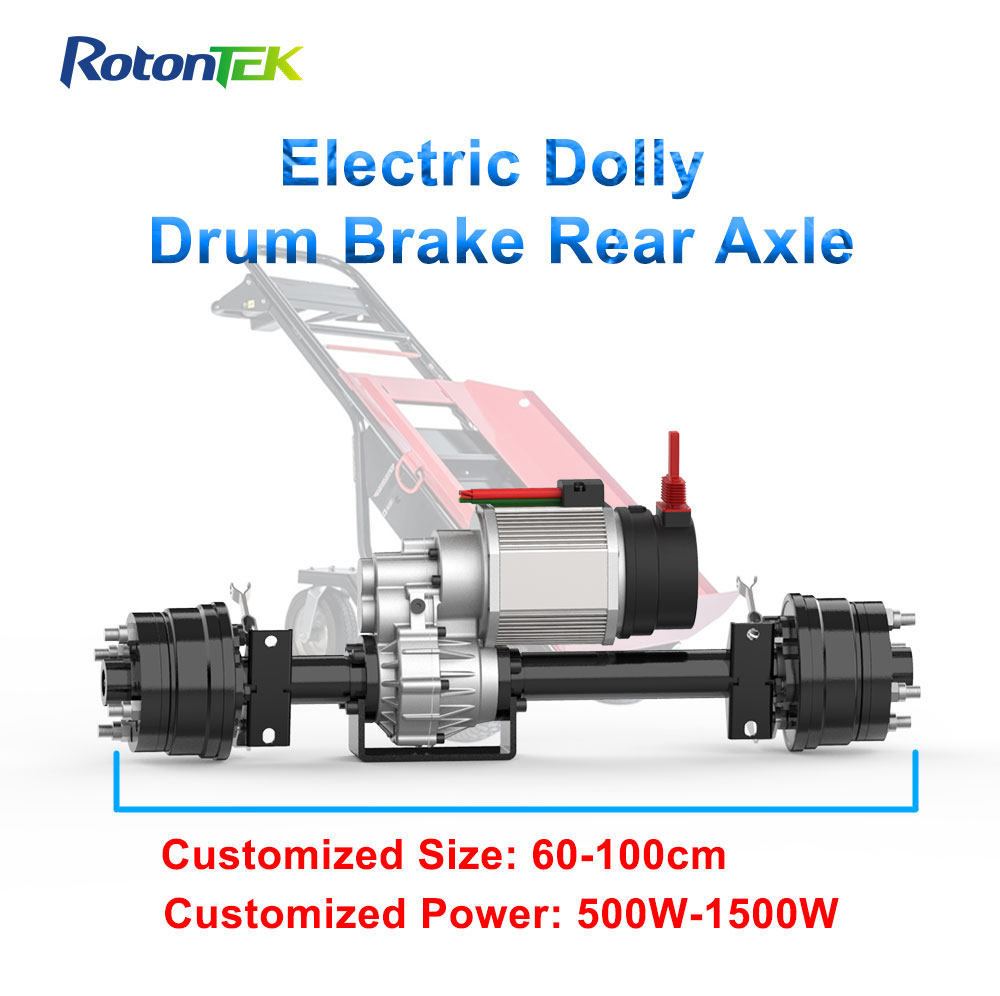

Electric dollys improve performance and efficiency in application scenarios by introducing electric transaxle. Electric dollys equipped with high-performance electric transaxle, such as the Rotontek 1500W BLDC model, are more powerful and more maneuverable than traditional transaxle. Electric dollys equipped with electric transaxles are mainly used in logistics, airports, and industrial environments due to their reliable stability and high efficiency.

A leading logistics company reported in its annual report that after using electric dollys equipped with Rotontek transaxles, its overall operating efficiency increased by 25% and maintenance costs decreased by 30%. Today, the introduction of more stable drum brake systems and fully floating axles with greater overall load capacity has further improved the efficiency and performance of electric dolly.

BLDC Electric Transaxle Working Principle

The working principle of a brushless DC electric transaxle (BLDC) is the ability to convert electrical energy into mechanical energy through a brushless motor. Brushless DC motors reduce friction and overall maintenance costs, while brushed DC motors wear out relatively quickly, so brushless motors have a longer lifespan and are more efficient than brushed motors.The Rotontek 1500w BLDC transaxle is designed with a complex control algorithm for a more responsive and efficient control system for electric dolly, stable and controllable drive under various load conditions, and perfect adaptation to different terrains.

Modern electric transaxles also integrate advanced devices such as drum brakes and fully floating drive axles.Unlike many other drive shafts, the newly launched 1500W BLDC electric transaxle device contains a brushless DC motor. These new additional accessories maximize the performance of electric transaxles while being safer and more reliable.

Advantages of BLDC Electric Transaxle with Drum Brake Full Floating Axle

Built-in Brushless DC Motor, Longer Service Life than Other Drive Axle on the Market

Unlike many other drive shafts, the 1500W BLDC electric transaxle uses a brushless DC motor, which has a significantly longer service life compared to brushed motors. The gears of this electric shaft have a high wear-resistant surface, ensuring extended durability without the need for frequent replacement. In addition, it does not consume any power when idle, making it an energy-saving choice for a variety of applications.

Rotontek Drive Axle has Lower Noise, More Efficient and Professional

The 1500W BLDC electric transaxle ND42Q is equipped with drum brakes and full floating axle for high efficiency and silent operation.It is equipped with a DC 48V 1500W motor with up to 91.47% efficiency and up to 165Nm torque. The transmission ratio is 43.9 or 26.35 ±1.5%, which can provide strong torque at low speeds, making it ideal for professional operations. Its advanced electromagnetic braking system and low noise level of only 62 dB make it ideal for noise-sensitive environments.

Drum Brakes Enhanced Braking Efficiency and Safety

Drum brakes optimize performance by focusing on stability and durability of electric dolly.Studies have shown that drum brakes provide better performance in wet and muddy conditions compared to disc brakes. For example, the Rotontek 1500W BLDC transaxle with drum brakes ensures safe and effective braking, reduces the risk of accidents and improves overall safety and stability under heavy load conditions.The enclosed design of drum brakes protects the brake mechanism from dust, dirt and debris, especially in heavy industrial and outdoor environments. This design reduces maintenance requirements and extends the durability of the brake system.

Improved Full Floating Axle for Higher Load Capacity and Greater Durability

E-axles with integrated drum brakes and fully floating axles are more durable and have a higher overall load capacity than those with drum brakes alone. Fully floating axles only transmit the torque of the differential to the wheels and do not bear the weight of the vehicle itself, so they can withstand greater torque and stress without the risk of bending or breaking. At the same time, it is easier to repair and replace without affecting other components such as the suspension or wheel bearings, thereby improving reliability and durability overall.

Benefits Over Traditional Electric Transaxle

As shown in the upper left picture, traditional electric drive axles lack the advanced features and durability provided by drum brake full floating axles, which provide better braking performance and reliability, can withstand different levels of load and adapt to various uneven terrains.

As shown in the upper right picture, Rotontek’s latest electric drive axle structure with drum brake full floating axle, Rotontek 1500W BLDC drive combines powerful braking and excellent full floating axle technology, setting a new standard for electric dolly. Its own innovative features, such as low noise, high wear-resistant tooth surface gears, high load capacity, high torque at low speed, and no power consumption at idle speed, have also become further advantages for customers to choose it.

One-Stop Solution for Electric Dollys Optimization

The most efficient and convenient way to optimize electric dollys is to integrate advanced components to achieve different needs. For example, Rotontek’s 1500W BLDC electric drive with drum brake and full floating axle is an ideal solution for modern electric dollys, providing comprehensive enhancements in many aspects.

Not only that, Rotontek has also launched a one-stop solution for electric dollys, as shown in the right picture. According to the news, the 8 core components of the electric dolly will be launched and sold as a complete set for customers to choose. Next, the functions of the remaining 6 core components will be roughly explained, and the reasons for choosing other components as a one-stop solution except drum brakes and full floating axle will be explained.

Brushless Motor Rear Axle:As the core power of the system, the main output is the brushless motor rear axle, which ensures stable, controllable and low-noise driving under all terrains and various load conditions.

Brushless Controller: An efficient control system that precisely adjusts the motor’s operating status, ensuring smooth starting and stopping, thereby enhancing the dolly‘s overall stability, durability and reducing operating costs.

Waterproof Switch: Designed with user-friendliness in mind, it ensures safety and reliability no matter the working environment. The switch is rated IP67, which means it is completely dustproof and can withstand immersion in 1 meter of water for 30 minutes.

Brake handle: Ergonomically designed for comfortable operation, easy control of the dolly stop and quick clamping, improving the overall safety of the equipment. In tests, the brake handle system has been shown to reduce stopping distances by up to 20% compared to traditional systems.

Voltage Indicator: Displayed on screen, real-time monitoring of battery charge ensures the cart is always ready for use, helping prevent unplanned downtime due to dead batteries. Studies show that effective battery monitoring can increase uptime by 10%.

Wheels: Made from a special rubber compound that increases durability and provides 30% better traction on slippery surfaces compared to standard wheels.

Emergency Switch: Providing an immediate response when an unforeseen accident occurs, the emergency switch can quickly cut off the power supply to ensure safe operation. It can cut off the power supply in less than 0.5 seconds, greatly reducing the risk of accidents.

Accelerator Handle: Provides a sensitive speed control handle, allowing the user to adjust the speed of the electric dolly according to actual needs, thereby improving the working efficiency of the electric dolly.

This one-stop solution not only optimizes the performance of electric dolly, but also improves their reliability and safety, while making the choice more straightforward for customers. One manufacturing plant using Rotontek electric dollys saw a 15% reduction in worker injuries related to manual material handling, demonstrating the safety benefits of using advanced electric dolly. With Rotontek’s advanced components, users can expect to increase efficiency, reduce operating costs, and enhance safety throughout their operations. Data-backed performance improvements and real-world examples highlight the tangible benefits of implementing such advanced technology.