Introduction to EZGO Electric Transaxles

EZGO electric transaxles are among the main units essential for the operation of electric golf carts and utility vehicles. As products designed to provide a vital level of torque and speed control needed to operate, they can perform at their best in various loads and terrains. Beyond the sphere of leisure, EZGO transaxles can be found in various settings, offering their efficiency and durability to a greater electric vehicle market.

Types of EZGO Electric Transaxles

EZGO Electric Transaxles can be grouped into several types, each designed for an appropriate level of performance and various vehicle models. Series electric transaxles are known for their exceptional torque. They are best suited for hilly terrains and greater loads. On the other hand, PDS transaxles contain additional features of speed control and great energy savings. The correct identification of the type of EZGO transaxle in the given electrical cart or vehicle provides additional benefits for troubleshooting and maintenance with Rotontek.

Common Usage Scenarios

Electric transaxles might be most commonly used in golf courses, where they contribute to the smooth handling and control of golf carts and electric vehicles in the surrounding areas. In addition, in large estates and industrial facilities, they help workers to maintain a steady speed and navigate type-specific terrains at an appropriate level of safety and effectiveness. Consequently, the knowledge of the most common usage scenarios can help in identifying potential problems and offering the right solutions from the part catalog in a timely fashion.

Identifying Common Problems in EZGO Electric Transaxles

Speaking about maintaining the optimum performance of EZGO electric transaxles, one should discuss the importance of identifying early signs of trouble, which can save both time and money. The maintenance demands the fast recognition and precise troubleshooting that reconditioners demonstrate in their work.

Symptoms of Failing Transaxles

The most obvious symptoms of an EZGO transaxle’s failure include any grinding or clicking noise, decreased acceleration, and a considerable loss of power. For instance, if a transaxle makes the grinding noise, the operator is likely dealing with worn-out bearings or a transaxle that lacks proper lubrication. When it takes time for the vehicle to accelerate, one is witnessing the faulty performance of a transaxle’s electric components or an alignment issue in the drive system . In both cases, it is vital to identify these symptoms and take action as soon as possible to prevent more severe damage that would substantially increase the cost of repairs.

Diagnostic Tools and Techniques

When it comes to specialized tools for the diagnostics of EZGO electric transaxles, one should talk about the multimeter, which is critical to measuring the electrical continuity and voltage outputs of any transaxle. In addition, with the help of an infrared thermometer, one can identify the overheating issues that usually imply friction problems or the abuse of a transaxle. When both of these tools should be utilized for a narrow consideration, an ideal approach to the mean would be to connect the vehicle to a diagnostic scanner for understanding the real-time performance of a transaxle and isolating one’s particular malfunction. Overall, these tools help to evaluate the condition of a transaxle and identify the necessary corrective actions with Rotontek products.

Using Rotontek Products to Fix Transaxle Problems

Rotontek is constantly developing new products that can solve the most common problems with EZGO electric transaxles, keeping your vehicle in good condition. This brand has sophisticated solutions that are designed to challenge and solve everyday issues. All Rotontek products are aimed at increasing the longevity of electric transaxles. This brand combines an already advanced technology with a simple application.

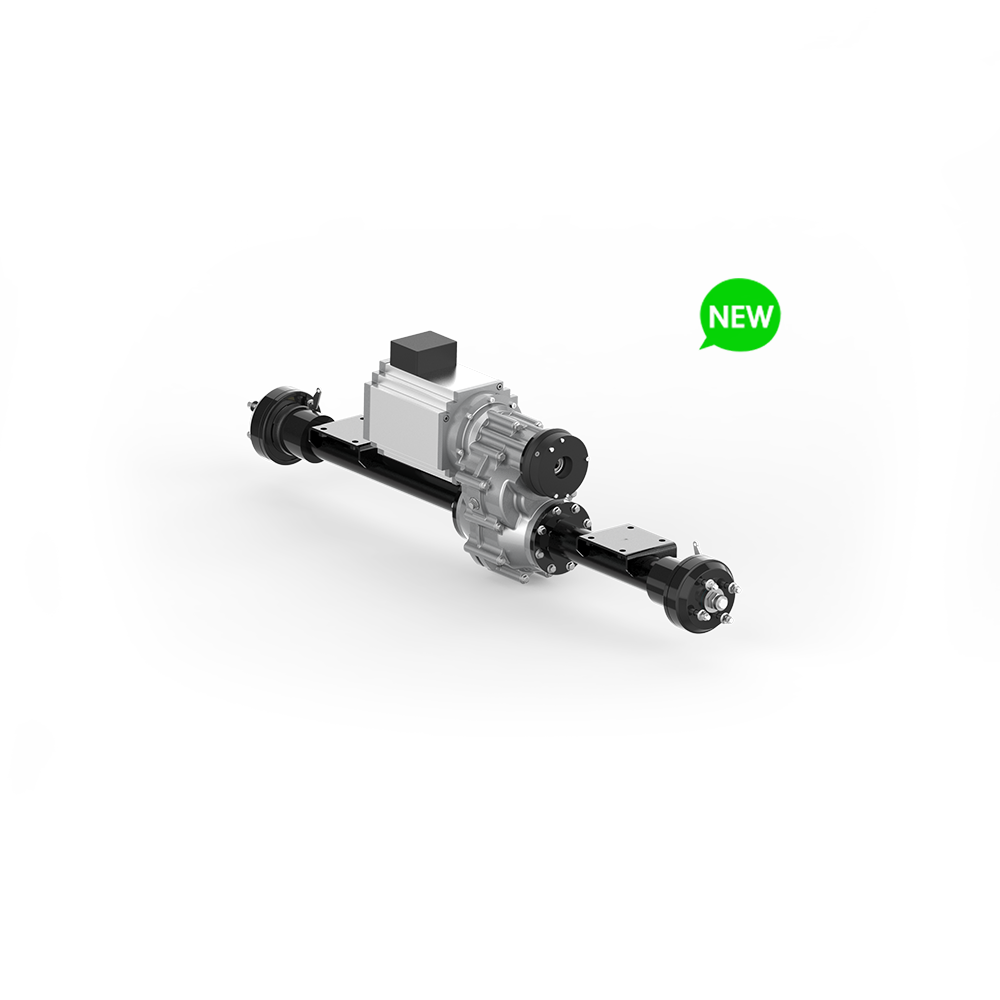

Overview of Relevant Rotontek Products

Rotontek has a full range of high-quality replacement parts specifically designed for EZGO transaxles. The synthetic grease developed by the brand significantly reduces friction and wear on moving parts, thus extending the transaxle’s service life dramatically. Rotontek also produces an upgraded motor controller and wiring harness which not so much replaces the bypassed or burned-out part as it functions with improved capacity and performance in general. All products are made by the brand under the control of highly qualified engineers and is generally of very high quality, far exceeding the permissible standards.

Installation and Repair Instructions

Installing Rotontek products involves a sequence of specific actions that will ultimately result in the correct operation of the device. The first, most important, and at the same time, the simplest action, is to disconnect the battery to ensure absolute security in the installation process. For example, when replacing a bearing, the transaxle assembly must be removed to access the bearing. Then a bearing puller is used to remove the old bearing safely. It is very important to properly seat a new Rotontek bearing. Of course, the replacement process may frighten newcomers. However, Rotontek has very clear video instructions, as well as short written manuals with clear step by step. Having carefully studied the training material, even the most inexperienced user will be able to cope with the repair process. These instructions have always been worthy of consideration, as all repairs are effective only if they are performed correctly.

Maintenance Tips for EZGO Electric Transaxles

In order to make your EZGO electric transaxle serve you for many years and work effectively, it is crucial to keep it in good conditions. I can offer you to follow these maintenance tips to increase the lifespan of your transaxle and avoid high charges on its repair or replacement.

Regular Maintenance Schedule

It is better to use a regular maintenance schedule to keep your EZGO electric transaxle in good conditions. Every six months or 250 hours of operation, you should check and replace its fluid. It is crucial to provide your transaxle with proper lubrication to keep your tool functioning effectively. Moreover, you are to check the transaxle for wear or damage, including such sings as leaks or noisy operation. Also, it is important to keep the air venting system clean and free of debris to prevent issues associated with overheat and mechanical wear. The regular maintenance schedule will help you identify minor problems and fix them before they grow larger.

Tips for Long-Term Transaxle Health

To make your EZGO electric transaxle serve you for a longer period of time, you may take a few other steps. For instance, you should always use high-quality replacement parts when fixing your transaxle to make them compatible with your tool. I recommend you using replacement parts offered by Rototek. also should not fill your vehicle with unnecessary items, as they may overload your transaxle. I also advise you o monitor your vehicle’s alignment and tire pressure to make sure the components of your transaxle are not unnecessarily strained. Unlike many people, you follow these simple tips to extend the lifespan of your EZGO electric transaxle on a daily basis.