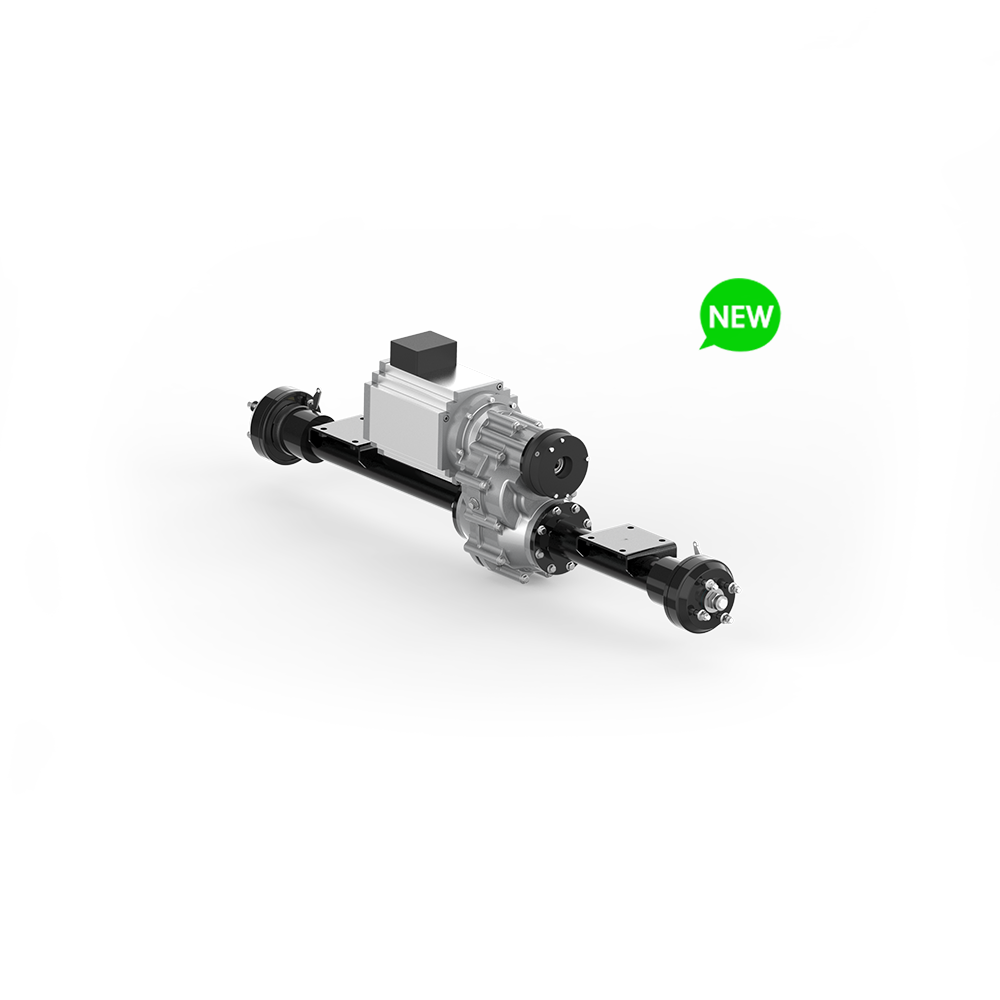

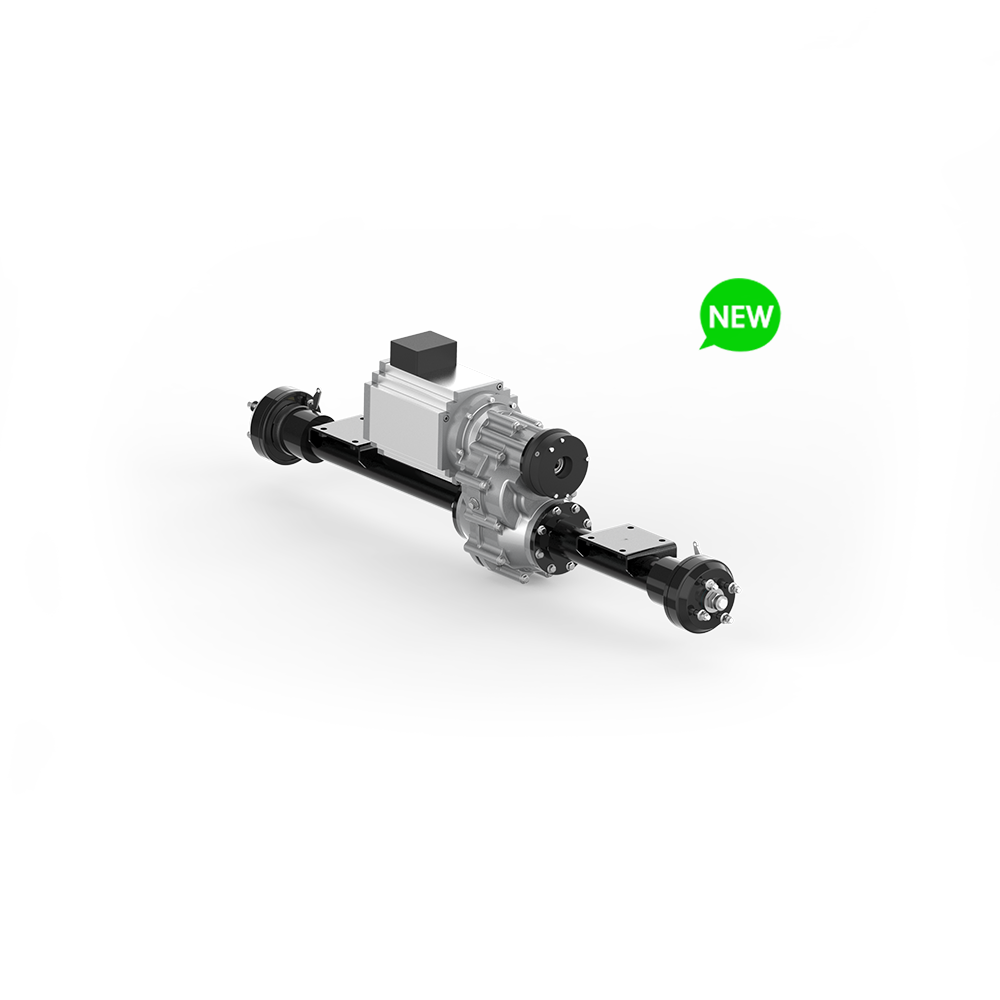

The main advantages of the low-noise electric transaxles are noise reduction, improved efficiency, and maintenance cost reductions. These drive shafts could reduce operational noise to less than 54 decibels, notably lower than the usual 80 decibels of conventional drive systems, promoting workplace comfort. Their energy efficiency increased to 85%, and due to the simplified structure, electric transaxles can extend the maintenance cycle and cost less to maintain economical and operational reliability by a big margin.

Warehouse Operation Efficiency and Quiet Environments

In modern warehouse management, low-noise electric transaxles have contributed a lot to operational efficiency and improvements in the working environment. Warehouse equipment can use low-noise electric transaxles to reduce operation noise to below 54 decibels, further improving the working environment and hence promoting the satisfaction and productivity of employees. Employees working in warehouses of retail giants such as Amazon and Walmart showed they felt less tired and stressed after the adoption of this kind of equipment and increased their work efficiency by about 18%.

The introduction of low-noise electric transaxles improves not only the warehouse environment but is also favored for their higher energy efficiency. Advanced motor technology and accurate control systems can normally be integrated into the drive shaft whose power usually ranges from 150 watts up to 20 kilowatts for various types of warehouse automation equipment. Compared to traditional equipment, electric forklifts and picking robots reduce energy consumption by about 30% with such drive shafts, thus reducing operating costs greatly in the long run.

The application of such technologies as low-noise electric transaxles is in the mainstream of today’s environmental protection trends. As the world becomes increasingly interested in sustainability and green energy, using eco-friendly equipment contributes not only to lower carbon footprints but also improves the company’s green image. A 2019 industry survey found that more than 60% of consumers would like to purchase products from environmentally certified companies. Thus, managers of warehouses would be more willing to buy these low-noise and highly efficient devices.

Factory Internal Noise Control

Low-noise electric transaxles have been an important factor in improving the working environment for most industrial job sites, especially for those factories that have a higher demand for noise levels. Driveshafts run in size from 150 watts up to 20 kilowatts and are designed for a variety of industrial machinery, including robots used in automatic assembly lines and mobile equipment. The major merits of these drive shafts are that they decrease operational noise to very low levels, sometimes as low as under 60 decibels, and thus decrease auditory fatigue for the workers in long-duration precision operations.

Given their energy efficiency, the use of Rotontek electric transaxles in factories can thus normally cut operating costs by approximately 40% compared with standard drive systems. This is not only reflected in direct savings in electricity but reduces long-term maintenance costs, too, since it requires less frequent maintenance. The design life for these drive shafts is usually 20% longer than for the conventional drive systems, which is the main key to extending operating times without stoppages on production lines.

Applying low-noise electric transaxles contributes to the fulfillment of enterprises in terms of more and more strict environmental requirements. In Europe alone, almost every country has already promulgated industrial noise control standards, stipulating clear limits for noise inside enterprises. The application of low-noise drive shafts will make it easier to meet those standards, enhance their environmental image, and help improve the brand market performance effectively.

Low-noise transportation in Business Districts

In busy business districts, the use of low-noise electric transaxles has become a huge contributor to higher quality urban life particularly, cleaning vehicles fitted with such transaxles can cut operating noise to no more than 54 decibels, significantly lower than traditional fuel-driven vehicles whose noise levels reach as high as 70 decibels. This advantage allows the vehicle to work without disturbing anyone, even in the middle of the night or early morning, while improving cleaning efficiency and flexibility for the city.

It also helps lower energy consumption by installing low-noise electric transaxles in these cleaning vehicles for business districts, with energy efficiency increased by 40% compared with traditional fuel vehicles. This energy-saving effect directly brings about economic benefits. It can reduce operating costs by about 30%. Such drive shafts have a maintenance cycle of up to 5000 hours, far beyond the conventional fuel-driven system maintenance cycles and further reducing maintenance costs.

The application of low-noise electric transaxles to cleaning vehicles in business districts is also in line with the current demands of environmental protection and sustainable development. These vehicles reduce noise pollution while decreasing air pollution because they have zero-emission characteristics. The promotion of electric cleaning vehicles in New York City has been one of the key strategies in the reduction of greenhouse gas emissions to improve the quality of life for city residents.

Service Vehicle Driving Experience

In this case, for most of the service-type vehicles, such as golf carts, the dividends gained through low-noise electric transaxles are quite obvious. These drive shafts normally have power settings from 150 watts to 20 kilowatts and thus offer decently sufficient power output as the motor operates with ease. It is quite easy in this instance to keep driving noises less than 54 decibels by using low-noise electric transaxles in a golf cart to ensure more comfort while playing, which is very important during a quiet golf course environment.

Low-noise electric transaxles constantly improve the energy use of a golf cart. Compared to fuel vehicles, an electric vehicle can achieve an energy utilization rate as high as 85%, while for fuel vehicles, only 20% to 30% of the energy taken in is converted into work. Besides the high efficiency that reduces the amount of energy consumption, the operating cost also lowered significantly. Therefore, traveling a kilometer would result in costs of half or so compared to the cost of fuel vehicles.

The enhanced driving experience from this electric drive system is reflected in its smooth acceleration and braking performance. The immediate torque response allows electric golf carts with such drive shafts to accelerate or stop much more smoothly, virtually without any delay, which substantially increases driving comfort and ease of handling. Their zero-emission characteristics also help reduce the carbon footprint of leisure spots, such as golf courses, fitting into modern environmental requirements.