Understanding the fundamentals of a permanent magnet synchronous motor is important for selecting the right component for your application. As a supplier, we know that this knowledge helps you evaluate performance, efficiency, and integration requirements. This article provides a clear, factual overview of how these motors work. This information supports your decision-making process when sourcing components.

Magnet Rotor Construction

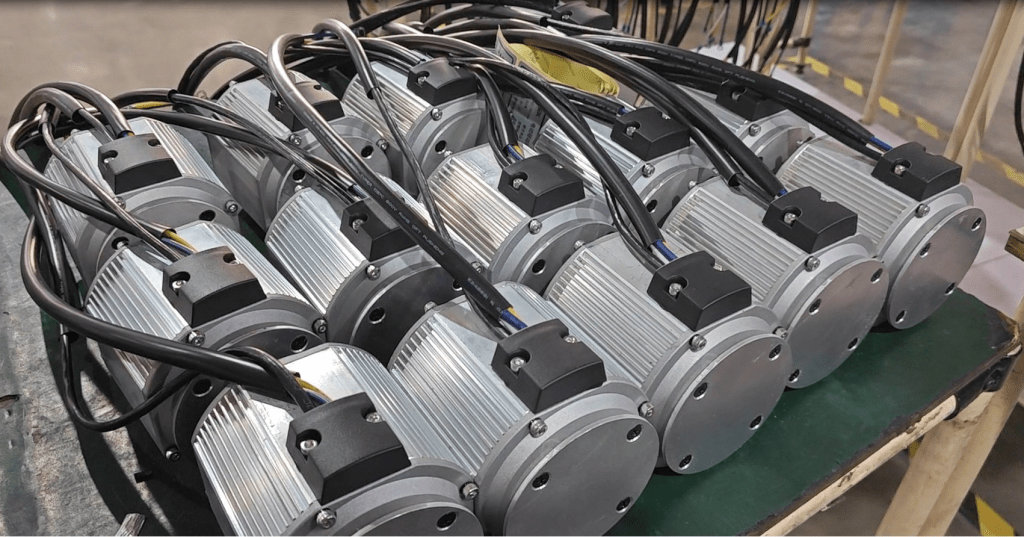

The defining feature of a permanent magnet synchronous motor is its rotor, which is embedded with powerful permanent magnets instead of windings. These magnets, often made from rare-earth materials like neodymium, create a constant magnetic field. The rotor’s construction can be either surface-mounted (SPM) or interior (IPM), with the latter embedding magnets inside the rotor laminations for structural integrity and higher speed capability. This design eliminates the need for rotor current and the associated losses, such as those from induction, which is a primary reason for its high efficiency. The robust magnetic field interacts directly with the rotating magnetic field generated by the stator, enabling precise torque production and reliable operation across various speeds and loads.

Stator Winding Design

The stator in a permanent magnet synchronous motor is similar to that of an induction motor, consisting of a laminated steel core with distributed windings. When alternating current is supplied to these windings, they produce a rotating magnetic field. The design and patterning of these windings are critical for creating a smooth, sinusoidal magnetic field that efficiently interacts with the permanent magnets on the rotor. In an interior permanent magnet synchronous motor, the stator field also utilizes magnetic reluctance torque, adding to the motor’s total output. Advanced control systems precisely manage the current in these windings to synchronize the stator’s rotating field with the rotor’s position, ensuring optimal performance, high power density, and minimal energy loss during conversion.

Synchronous Motor Operation

Operation is termed “synchronous” because the rotor’s rotation precisely locks in with the frequency of the alternating current in the stator windings. The rotor, with its permanent magnetic field, continuously aligns itself with the rotating magnetic field produced by the stator. This lock-step rotation eliminates slip, a phenomenon present in induction motors where the rotor lags behind the stator field. A rotor position sensor is typically used to provide real-time data to the controller, which adjusts the stator current accordingly to maintain this synchronization. This precise control allows for excellent speed regulation, high torque at low speeds, and stable operation across a wide range of conditions, making it suitable for applications demanding accuracy and efficiency.

Conclusion

The permanent magnet synchronous motor represents a significant leap in electromechanical design, offering a compelling combination of efficiency, power density, and control. Whether for precision industrial automation or the demanding world of electric transportation, this technology provides a foundational advantage. At Rotontek, we are committed to refining and applying this technology through our IPM motor series and integrated powertrain systems. We invite you to explore how our approach to efficient, reliable motor design can power your next project or product by visiting Rotontek to learn more about our specific solutions and capabilities.