Hydraulic pumps offer high power, precision, and durability but face issues like leakage, noise, and high maintenance costs.

Advantages of Hydraulic Pumps

High Power Density and Efficiency

Hydraulic pumps are renowned for their high power density, meaning they can generate a large amount of power relative to their size. This is particularly beneficial in applications where space is at a premium. In terms of efficiency, these pumps typically offer efficiencies between 70% and 95%, depending on the type and application. The efficiency is enhanced by the ability to maintain consistent power output with minimal energy loss.

Precision and Control in Operation

Precision and control are hallmark features of hydraulic pumps. They allow for fine control over movement and speed, which is critical in applications such as precision machinery and aerospace. This control is achieved through advanced fluid dynamics, enabling operators to achieve precise positioning with an error margin of less than 0.01%. Additionally, hydraulic pumps can operate at a wide range of speeds, from very slow to very fast, providing flexibility in application.

Durability and Reliability

Durability and reliability are key advantages of hydraulic pumps. They are designed to withstand harsh environments and operate reliably for extended periods. A typical hydraulic pump has a lifespan of 10,000 to 20,000 hours under normal operating conditions. The materials used, such as high-quality metals and alloys, contribute to their robustness and longevity. Furthermore, the design of these pumps minimizes the risk of breakdowns, ensuring consistent performance over time.

To further enhance the understanding, consider visiting the Wikipedia pages for Hydraulic Pumps and Fluid Dynamics to delve deeper into their workings and applications.

This detailed exploration of the advantages of hydraulic pumps emphasizes their efficiency, control, and durability, making them a viable choice for various industrial applications.

Disadvantages of Hydraulic Pumps

Risk of Leakage and Contamination

One of the primary disadvantages of hydraulic pumps is the risk of leakage. Even a minor leak can lead to significant fluid loss over time, impacting the system’s efficiency. Leaks not only waste hydraulic fluid, but they can also lead to contamination issues, affecting the entire hydraulic system. Contamination of hydraulic fluid can result in increased wear and tear on components, reducing the lifespan of the pump and associated machinery. The cost of frequent fluid replacement and potential environmental hazards due to leaks add to the disadvantages.

Maintenance and Operational Costs

Hydraulic pumps often incur high maintenance and operational costs. Regular maintenance is crucial for optimal performance, involving the replacement of parts like seals, gaskets, and filters. The cost of these components, along with the labor involved in maintenance, can be substantial. In terms of operational costs, hydraulic systems, depending on their size and complexity, can consume a significant amount of energy, impacting overall efficiency and operating costs.

Noise and Vibration Issues

Noise and vibration are common issues associated with hydraulic pumps. These pumps can generate noise levels up to 70-90 decibels, which is comparable to the noise in a busy traffic street. Prolonged exposure to such noise levels can be harmful to operators. Vibration, on the other hand, can lead to mechanical stress on the system, reducing the lifespan of components and potentially leading to system failures.

For a more in-depth understanding, exploring the Wikipedia page on Hydraulic Machinery can provide additional insights into these challenges.

In conclusion, while hydraulic pumps are powerful and versatile, they come with challenges such as leakage risks, high maintenance costs, and noise and vibration issues, all of which can impact their overall effectiveness and cost-efficiency.

Applications of Hydraulic Pumps

Industrial Applications

- Manufacturing Sector: Hydraulic pumps are extensively used in the manufacturing sector for machinery like presses, conveyors, and automated production lines. They provide the necessary power to handle heavy loads, offering precise control and high efficiency.

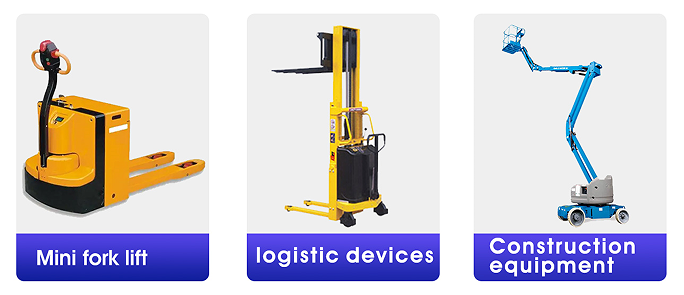

- Construction Equipment: In construction, hydraulic pumps are integral to equipment such as cranes, excavators, and bulldozers. Their ability to handle heavy loads and provide steady power makes them ideal for these applications.

- Mining and Quarrying: Hydraulic pumps are used in mining equipment like drills and earth movers. The rugged nature of these pumps allows them to withstand the harsh conditions typically found in mining environments.

Mobile Applications

- Tipper Trailers: Hydraulic pumps are crucial in the operation of tipper trailers, used for transporting and unloading heavy materials. They offer high power density, making them efficient for lifting heavy loads.

- Two-Post Auto Hoists: In automotive repair shops, two-post auto hoists rely on hydraulic pumps for lifting vehicles. These pumps provide the strength and stability required to safely lift and hold vehicles for maintenance.

- Forklifts: For material handling, forklifts use hydraulic pumps to lift and move heavy objects. The pumps in forklifts are designed for high efficiency and durability, ensuring reliable operation over long periods.

For further details on the various applications of hydraulic pumps, you can refer to the Wikipedia page on Hydraulic Drives.

In summary, hydraulic pumps play a crucial role in various industrial and mobile applications, offering benefits like high power density, efficiency, and precise control, which are essential in these settings.

Comparison with Other Pump Technologies

Hydraulic Pumps vs. Electric Pumps

| Feature | Hydraulic Pumps | Electric Pumps |

|---|---|---|

| Power Density | High (can generate more power per unit size) | Lower compared to hydraulic pumps |

| Efficiency | Generally 70-95% depending on application | Usually higher, can reach up to 90-95% |

| Cost | Higher initial cost but lower operational cost | Lower initial cost but higher operational cost due to electricity consumption |

| Maintenance | Requires regular maintenance for fluid, seals, etc. | Less maintenance-intensive |

| Lifespan | 10,000 to 20,000 hours | Varies widely, generally longer than hydraulic pumps |

| Noise and Vibration | Can be noisy and vibrate significantly | Typically quieter and have less vibration |

| Applications | Ideal for heavy-duty applications requiring high force | Best suited for applications requiring consistent and controllable speed |

Hydraulic Pumps vs. Pneumatic Pumps

| Feature | Hydraulic Pumps | Pneumatic Pumps |

|---|---|---|

| Power Density | High power output | Lower power output compared to hydraulic pumps |

| Efficiency | Higher efficiency in energy transfer | Less efficient due to energy loss in compressing air |

| Cost | Higher initial and maintenance costs | Generally lower initial and operational costs |

| Maintenance | More complex maintenance due to fluid dynamics | Simpler maintenance, fewer parts involved |

| Speed Control | Precise control over speed and position | Less precision in control |

| Noise and Vibration | Noisy and vibratory operation | Typically quieter with less vibration |

| Applications | Preferred in heavy lifting and high-force applications | Commonly used in lightweight, low-force applications |

For more detailed information, consider visiting Wikipedia pages on Hydraulic Pumps, Electric Pumps, and Pneumatic Pumps.

In summary, while hydraulic pumps excel in power density and application in heavy-duty tasks, electric and pneumatic pumps offer advantages in terms of efficiency, noise levels, and maintenance requirements. The choice between these technologies depends largely on the specific requirements of the application.

Technological Advances in Hydraulic Pumps

Innovations for Enhanced Efficiency

- Variable Displacement Pumps: Modern hydraulic systems are increasingly using variable displacement pumps. These pumps adjust the flow and pressure according to demand, leading to significant energy savings. This innovation can improve efficiency by up to 20-30% compared to fixed displacement pumps.

- Advanced Materials: The use of advanced materials like composites and special alloys in pump construction reduces weight and improves efficiency. These materials can withstand higher pressures and temperatures, extending the lifespan of the pump.

- Smart Control Systems: Integration of smart control systems in hydraulic pumps allows for precise control. These systems can optimize pump performance in real-time, reducing energy consumption and improving overall efficiency.

Developments in Minimizing Environmental Impact

- Eco-friendly Hydraulic Fluids: There’s a shift towards using bio-degradable hydraulic fluids which are less harmful to the environment. These fluids are designed to have a minimal impact in case of leaks.

- Leakage Reduction Technologies: Developers are creating new sealing technologies and redesigning hydraulic pumps to minimize fluid leakage. These improvements address one of the primary environmental concerns associated with hydraulic systems.

- Noise Reduction Measures: Advances in pump design have also focused on reducing noise pollution. Quieter hydraulic pumps contribute to a more environmentally friendly and operator-friendly workplace.

For more insights into the latest advancements in hydraulic pump technology, visit the Wikipedia page on Hydraulic Pumps.

To sum up, the field of hydraulic pumps is witnessing significant technological advancements aimed at enhancing efficiency and minimizing environmental impact. These developments are not only making hydraulic systems more sustainable but also improving their performance and lifespan.