They reduce operational noise through the use of forged alloy steel gears and precision grinding processes that develop the gearbox for the optimization of its performance and assemble the gears with high accuracy. Also, self-developed efficient motors and controllers reduce vibration and friction to a minimum extent.

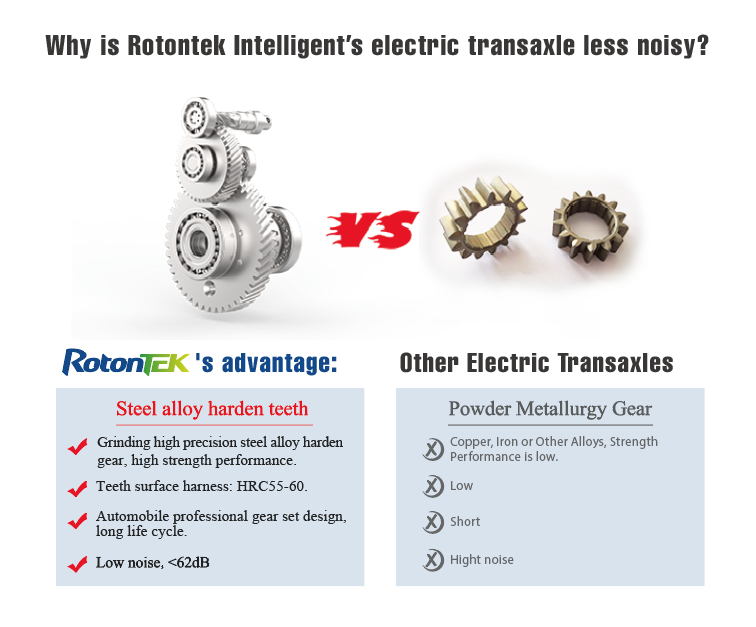

Forged Alloy Steel Gears

Electric transmission gears by Rotontek are manufactured from quality alloy steel through the forging process. This design and selection of material form the basis of noise reduction in that, besides providing superior mechanical performance, forging improves the durability of the product. Alloy steel improves abrasion resistance, dimensional and shape stability under high load operation, and reduces noise.

Alloy steel is a type of steel alloyed with a number of alloying elements, including molybdenum, chromium, nickel, and more. This enhances its strength, toughness, and resistance to corrosion. These elements give alloy steel stronger resistance to fatigue and superior thermal stability, maintaining its shape under conditions of long-term high load and avoiding gear meshing caused by thermal expansion or material fatigue that can lower noise. Especially in the case of high-speed rotation, alloy steel gears can reduce friction noise effectively.

Compared to casting, forging allows the operation of gears with higher mechanical strength and a more compact internal metal structure, which reduces vibration during operation. During forging, the grain structure of the metal is optimized for maximum stability of the gear mesh with the least amount of generated vibration or noise by slight deformation or surface defects. In addition, forging extends service life to a great degree as well, which will become highly relevant in electric transmission systems requiring operation over an extended period.

In long-term operation, the operational condition of gears is usually complex, including very high temperatures and friction. High thermal stability allows forged alloy steel to hold dimensions and mechanical properties for a long time under high temperatures, which further reduces noise. High hardness enables the material to allow tighter gear meshing in order to reduce noise due to vibration and friction.

Precision Grinding Process

The electric transmission gears used in Rotontek products are made of high-strength forged alloy steel, and their manufacturing process involves precision grinding. Gear accuracy is among the major factors for noise reduction. The precision grinding process ensures surface roughness reaches a micron level, which can greatly reduce friction coefficients and noise during meshing.

The operational smoothness of gears directly depends on the accuracy level. Rotontek precision grinding process controls gear meshing errors to a very low range. Reaching grade 6 in the precision standard makes the gear meshing even smoother, which reduces noise caused by mechanical vibrations. The surface treatment of gears is done in the last stage of manufacture, which is precision grinding. It reduces the surface roughness to the micron level and reduces friction between gears, making the meshing process smooth, hence reducing noise further.

Noise in the gear meshing is directly proportional to the roughness of the surface of a gear. In the case of precision grinding, the bumps and depressions on the gear surface will decrease: during high-speed operation, contact between gears will be carried out smoothly, reducing abnormal noises that may be due to uneven friction. In addition, high-precision gears serve to prolong the service life of loaded gears because load distribution is turned to be more evenly supported and lowers the wear rate of the gears, reducing emergence noise caused by wear in some places with time.

After years of research and experiments, Rotontek was able to determine that the grade 6 precision grinding process could decrease the noise of gear meshing by about 30%. During mass production, Rotontek guarantees that every gear meets the machining standard of grade 6 to ensure the electric transmission system has an overall low-noise level.

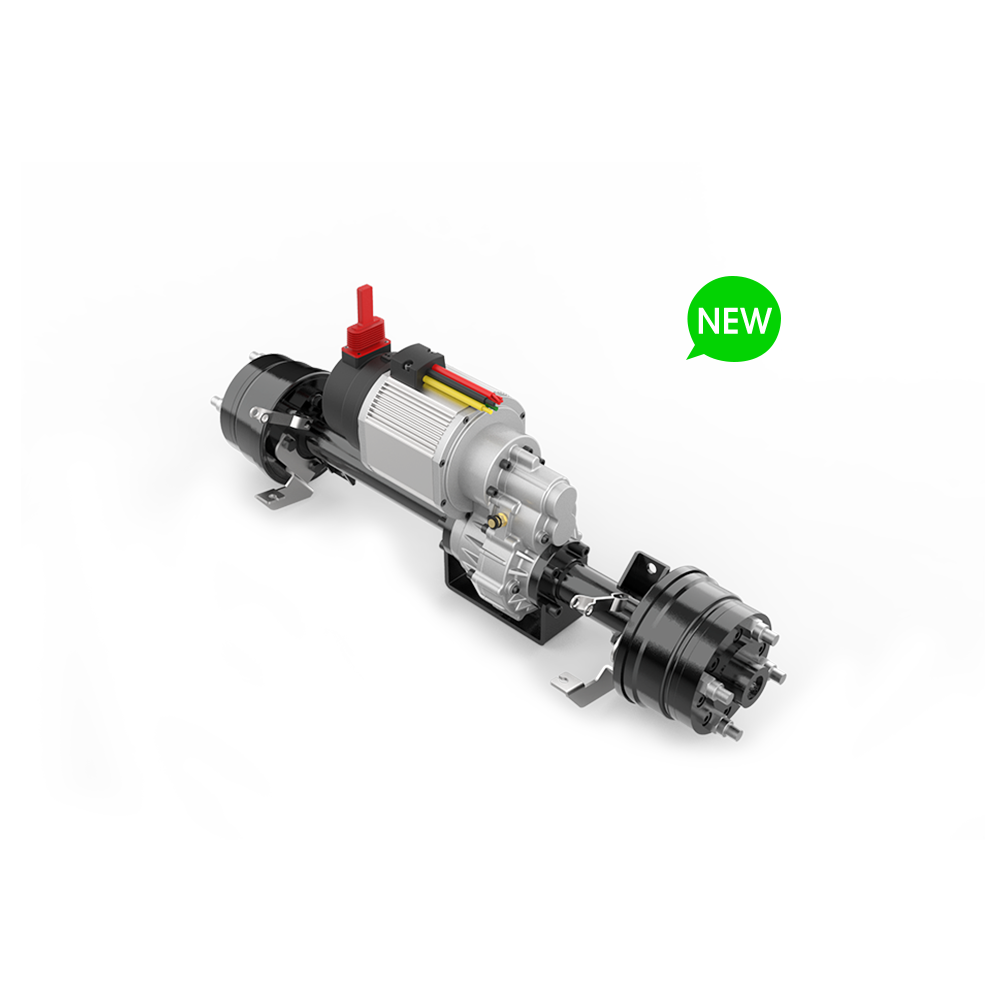

Precision Assembly and High-Precision Gearbox

The adoption of high-quality gears and materials alone will not fully achieve this target for low-noise operation. Rotontek puts enough effort into the assembly process of electric transmissions so that the design and assembling of gearboxes reach extremely high precision. The gearbox is the core component within an electric transmission; the precision and quality of its assembly directly affect the level of vibration and noise in the transmission system.

In gearbox design, Rotontek pays much attention to optimization of the internal structure by reducing gaps among gears, bearings, and other components to make sure all parts mesh tightly for lowering vibration and noise caused by looseness or friction. Besides, the high-precision differential design makes it possible that running wheels at both sides run smoothly with differentiated speed and keep away from noise problems caused by excessive speed difference.

In the process of assembly, advanced precision assembly by Rotontek can ensure micron-class fitting accuracy between gears and other transmission parts. Meanwhile, in the course of the assembly, Rotontek used advanced measuring devices to make strict checks on the dimensions and positions of all components, ensuring that all the moving parts were within the permissible range of tolerance. By tightly controlling the assembling processes, the Rotontek provides stability and low noise for electric transmissions under high load and at high speed.

The precision of gearbox assemblies determines not only the noise level but also the service life and reliability of the whole system. High-precision assembling processes will reduce friction and an uneven load in a transmission system, thus reducing wear rates and increasing the service life of the equipment.

Self-Developed Motors and Controllers

In addition to the mechanical structure, the motors and controllers of the electric transmission systems also directly affect the noise level. The company enjoys an advantage in developing motors and controllers on its own, particularly with respect to precision in motor control and smoothness, both of which will effectively reduce noise caused by the unstable controlling of the motor through advanced technology.

Rotontek uses advanced AC vector controller technology that can precisely control speed and torque in the motor. This would provide a smooth motor start-up and operation with no vibration and noise compared to the traditional motor acceleration and deceleration. When comparing traditional control technologies with AC Vector control, it can effectively distribute the motor phase currents during smooth operation under different loads and working conditions. This technology further improves the noise-reduction effect of electric transmissions and strengthens the power performance of the vehicle or equipment.

The self-developed high-efficiency motor focuses on low loss, high efficiency, high performance, and long-time low noise under full-load operation. Rotontek motor optimizes the electromagnetic design and uses high-quality materials to reduce internal vibration and friction, thus reducing the noise when operating the motor significantly.

In addition, noise-reduction technology has been introduced into the design of Rotontek motor cooling system so that the motor can bear high and low loads for a long time while maintaining low temperature and noise. It is because of such advanced designs that the electric transmissions provided by Rotontek are capable of guaranteeing quiet operation under different complicated working conditions with the sake of more comfortable users’ experiences.

[…] High-efficiency electric drive systems typically cost $1,000 to $1,500, while lower-cost systems range from $500 to $800. Cost-effective drive systems can reduce operating costs by 15%-20% over five years. […]