In the world of heavy hauling, construction, logistics, and specialized vehicle support, stability and effortless lifting are non-negotiable requirements. Historically, this meant painstaking manual cranking or complex hydraulic setups. Today, however, the industry is transitioning to automated, precise solutions, and leading that charge is the electric jack.

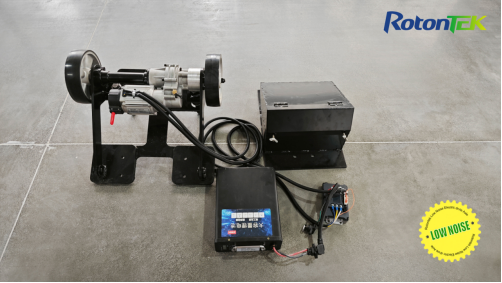

An electric jack is a motorized lifting and stabilizing device that replaces manual effort with electrical power. By integrating an electric motor with a high-strength mechanical transmission, it provides controlled, effortless movement for lifting, leveling, and supporting heavy loads. At Rotontek, we view this technology as a core component of efficiency and safety across various heavy-duty industries, offering a series of jacks designed for specific torque and stability challenges, from semi-trailers to specialized platforms.

The Mechanism: How Electric Jacks Convert Power to Lift

The core function of an electric jack is to take the rotational power of a motor and convert it into linear thrust—a process that must be highly reliable, self-locking, and efficient.

1. The Motor and Transmission System

Unlike manual jacks that rely on muscle power turning a handle, electric leveling jacks utilize a DC electric motor connected to a gearbox. This gearbox reduces the high-speed, low-torque output of the motor into a low-speed, high-torque force suitable for lifting thousands of kilograms.

Worm Gear/Screw: The reduced torque is applied to a high-strength screw shaft. As the screw rotates, a nut or collar travels up or down the shaft, extending or retracting the jack’s inner leg.

Self-Locking Feature: A crucial safety feature is the inherent self-locking capability of the worm gear or screw drive. This mechanism ensures that when the motor power is removed, the load cannot force the jack back down, keeping the raised object securely in position without the need for a continuous power supply. This stability is vital when stabilizing heavy vehicles or construction platforms.

2. Control and Safety

Modern electric jack systems move far beyond simple on/off switches. They feature advanced controls, including:

One-Touch Operation: Simplified controls, allow for single-button deployment and retraction, dramatically improving speed and ease of use.

Intelligent Sensing: In electric leveling jacks, built-in sensors or Hall Effect technology monitor the extension of multiple jacks simultaneously, allowing a centralized control unit to automatically adjust the height of each leg until the vehicle or platform is perfectly level.

Safety Brakes: Patented power-off brakes are often incorporated to ensure immediate lock-down in the event of power loss, adding an extra layer of safety during operation.

Versatility in Application: The Rotontek Leveling Jack Series

The versatility of the electric jack system is best demonstrated by the wide range of heavy-duty applications it serves. Rotontek offers distinct series tailored to specific industrial and transport needs, focusing on high tonnage capacity and robust durability.

1. Semi-Trailer Landing Gear: Heavy-Duty Stabilization

One of the most demanding applications is supporting semi-trailers during loading and unloading when they are detached from the tractor. This requires supporting a significant portion of the trailer’s maximum gross weight, often on uneven terrain.

The Rotontek Semi-trailer 10T Leveling Jack (ND1OT-NG350) exemplifies our commitment to high-capacity stabilization.

ND1OT-NG350 Key Specifications:

Carrying Capacity (Single Jack): 10 Tons

Lifting Mechanism: Ball screw for high efficiency

Operation: One-button operation (approx. 80 seconds to position)

Protection Grade: IP56 (Corrosion-resistant and weather-proof)

Stability Feature: Patented screw reverse mechanism for superior shock absorption.

This type of electric leveling jack prevents “trailer tipping” during forklift operations and eliminates the back-breaking manual cranking, which is a significant ergonomic and safety advantage in high-volume logistics centers. We also offer a 20T Electric Landing Gear series, which features a pioneering transmission design incorporating a ball screw mechanism for superior energy-efficiency compared to conventional trapezoidal screws.

2. Specialized Industrial and Agricultural Platforms

Beyond transportation, the demand for stable, adjustable support extends to complex machinery that must operate with precision on un-level ground.

Agricultural Machinery: Large-scale planting and harvesting equipment often needs quick, accurate leveling before deploying specialized booms or components to ensure uniform results across sloped fields.

Construction Equipment: Modular construction sites, temporary structures, and specialized heavy lifting equipment require rapid, fail-safe stabilization. The portability and power of an electric jack series provide the necessary rigidity and ease of deployment.

Aircraft Docking Systems: High-precision leveling and stabilization are essential for safety during aircraft maintenance and docking procedures.

3. Recreational Vehicle (RV) and Camper Leveling

While often seen in consumer applications, the underlying technology comes from the same robust industrial design principles. The need for precise, fast leveling in the RV industry—to ensure appliances function correctly and for user comfort—has driven the widespread adoption of multi-point electric leveling jacks. These systems use sensors to automatically determine the low corners and extend the jacks in sequence, achieving level in minutes, rather than the tedious manual process of using blocks and cranks.

The Rotontek Advantage: Durability and Customization

At Rotontek, our philosophy in the electric jack and leveling field centers on durability and tailored performance. Our jacks are manufactured from high-strength, high-quality steel with corrosion-resistant surface treatments, such as the electrophoretic process on our 10T jack, ensuring stable, long-term operation even in harsh outdoor and heavy-duty environments.

By offering a versatile series of jacks—from the high-efficiency ball screw designs in our trailer landing gear to the precision control found in our smaller lifting solutions—we ensure that every partner can find the specific torque, lift capacity, and control system required for their unique stabilization challenges.