The best Hydraulic Power Unit in 2024 combines cutting-edge efficiency, robust construction, and smart technology, offering unparalleled reliability and adaptability for a wide range of applications, ensuring top performance in demanding environments.

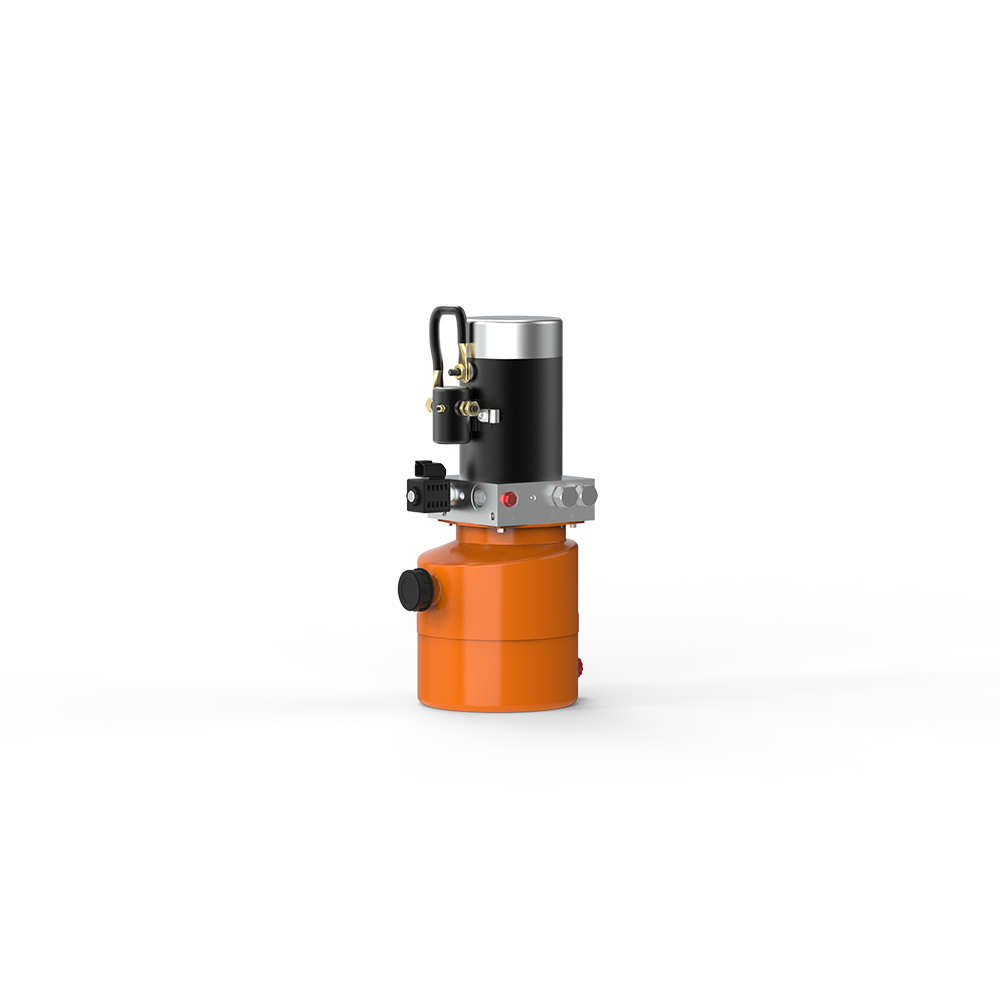

Top hydraulic power units are engineered for high efficiency and reliability, meeting diverse industrial needs. Their compact design saves space while delivering essential hydraulic force for lifting and pressing operations.

Featuring pre-installed motors, pumps, reservoirs, and pressure relief valves, they ensure optimal performance and longevity. Easy to install and maintain, these units are suitable for both mobile and stationary applications, enhancing hydraulic system efficiency.

Working principle of Hydraulic Power Units

Hydraulic Power Units (HPUs) operate on Pascal’s law, distributing pressure uniformly in confined fluids. Here’s a brief overview:

- Motor: Powers the pump, converting mechanical energy to hydraulic.

- Pump: Pressurizes hydraulic fluid.

- Reservoir: Stores hydraulic oil.

- Valves: Control flow direction.

- Actuators: Convert hydraulic pressure to mechanical energy for tasks.

- Return Path: Fluid cycles back to the reservoir for reuse.

HPUs are closed-loop systems, with fluid continuously recycled. Valves regulate the process, enabling precise force manipulation.

Common Uses of Hydraulic Power Units

Hydraulic Power Units (HPUs) are widely used across various industries due to their ability to produce large amounts of power through small, flexible hoses and tubes. Here are some common uses:

Manufacturing: HPUs are integral in the operation of machinery used in manufacturing processes, such as presses, conveyors, and plastic injection molding machines.

Construction: They power heavy construction equipment like excavators, bulldozers, and cranes that require substantial force to dig, lift, and move materials.

Aerospace: In the aerospace industry, HPUs are used for maintenance equipment, including the actuators that control the movement of aircraft components.

Agriculture: Farming equipment such as tractors and harvesters use HPUs to perform tasks that require robust and sustained force.

Marine: HPUs drive the steering mechanisms and control surfaces of many ships and also operate watertight doors and stabilization systems.

Mining: HPUs are crucial in mining operations, powering drills, lifts, and other equipment in both underground and surface mining.

Waste Management: Hydraulic systems are used in garbage trucks and recycling equipment to compact waste materials.

Hydraulic Power Units are appreciated for their reliability, efficiency, and ability to exert a high force relative to their size, which makes them suitable for a broad range of applications requiring motion control.

Advanced Control Systems for Hydraulic Power Units

Advanced control systems for Hydraulic Power Units (HPUs) significantly enhance the functionality and efficiency of these units. These control systems employ sophisticated technology to manage and monitor hydraulic flow and pressure, ensuring optimal performance of the HPU. They can be programmed for precision control, allowing for automation of complex tasks and providing feedback for system adjustments. Features often include programmable logic controllers (PLCs), sensors for real-time data, and interfaces for human-machine interaction.

Advanced control systems can improve the safety, reliability, and energy efficiency of HPUs. They can also facilitate predictive maintenance by analyzing data trends and detecting anomalies that indicate potential issues.

Below is a comparison table highlighting the differences between compact Hydraulic Power Units and other (standard) Hydraulic Power Units:

Compact HPUs are usually the go-to choice for applications where space is at a premium or where the hydraulic power demands are lower. Standard HPUs, on the other hand, are more suited for industrial settings where higher power and more robust systems are required. The choice between the two will depend on the specific needs of the application, including space, power requirements, and budget.

Calculating Power and Pressure for Hydraulic Units

Calculating power and pressure for hydraulic units is key to their design and operation.

- Pressure (P) is calculated as force (F) divided by the area (A) the force is applied to, expressed as P= F/A.

- Power (Pw) needed by a hydraulic pump is the product of the flow rate (Q) and pressure (P), divided by the efficiency (η) of the pump, given by Pw= Q×P/η.

For those seeking high-quality, reliable hydraulic power units that align with calculated specifications, we recommend exploring our range of products. Our hydraulic power units are designed for efficiency, reliability, and versatility, catering to a wide range of industrial applications.

119D Forklift Hydraulic Power Unit

30% longer operation, all-aluminum tank for heat dissipation, high-power motor, low noise, reduced consumption.

170 series hydraulic unit

1.5-2.2kW motor, 1.2-2.7cc/rev flow, high-pressure gear pump, versatile for various applications.

170A series hydraulic power unit

1.5-2.2kW power, 1.2-2.7cc/rev flow, automatic pump, and integrated valves, suitable for ships, trailers, and auto hoists, with a 30s/3min cycle.

119 Hydraulic power unit

0.8-1.2KW power, 0.5-1.0 cc/rev flows, for intermittent systems, supports manual operation, and is ideal for mini forklifts, RVs, and more.

109 B series Compact hydraulic power unit

Offers a compact design with a DC motor, gear pump, and valves, ensuring load maintenance and zero leakage, suitable for unidirectional and bidirectional systems.

Selecting the Right Hydraulic Power Unit

When choosing a Hydraulic Power Unit (HPU), consider:

- Power Capacity: Assess the system’s required operational pressure and flow rate.

- Size and Portability: Evaluate available space and mobility needs.

- Fluid Type: Confirm compatibility with your hydraulic fluid.

- Reservoir Volume: Match fluid volume needs, allowing for thermal expansion.

- Pump Type: Choose (gear, vane, piston) based on efficiency and noise.

- Control Options: Opt for manual or automated controls for precision.

- Heat Dissipation: Plan for managing heat with coolers or exchangers.

Consult a specialist or manufacturer guidelines to ensure the HPU meets your system’s specifications.